[Molecular Weight] 122.063

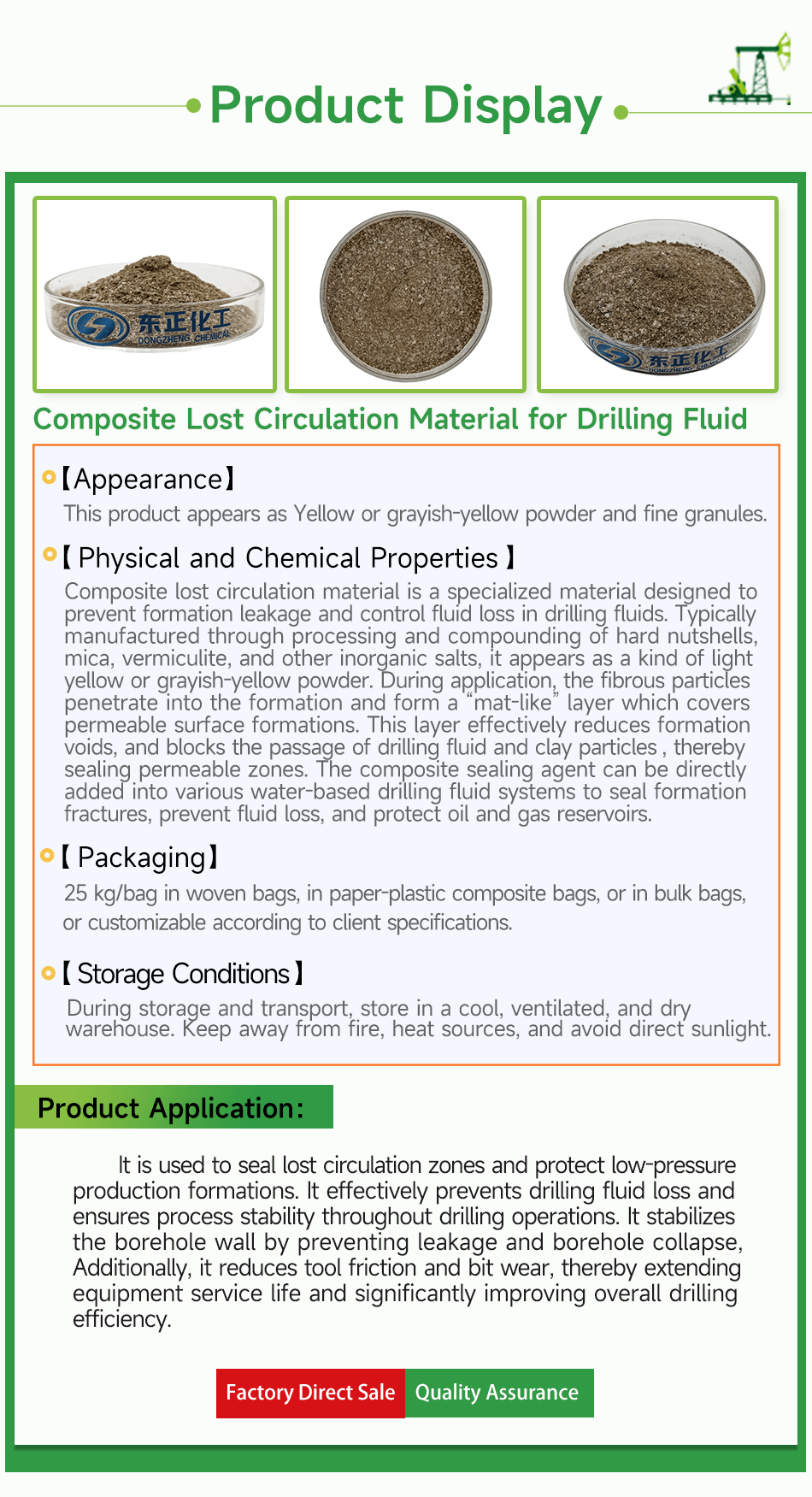

[Appearance] This product appears as Yellow or grayish-yellow powder and fine granules.

[Physical and Chemical Properties]

Composite lost circulation material is a specialized material designed to prevent formation leakage and control fluid loss in drilling fluids. Typically manufactured through processing and compounding of hard nutshells, mica, vermiculite, and other inorganic salts, it appears as a kind of light yellow or grayish-yellow powder. During application, the fibrous particles penetrate into the formation and form a “mat-like” layer which covers permeable surface formations. This layer effectively reduces formation voids, and blocks the passage of drilling fluid and clay particles, thereby sealing permeable zones. The composite sealing agent can be directly added into various water-based drilling fluid systems to seal formation fractures, prevent fluid loss, and protect oil and gas reservoirs.

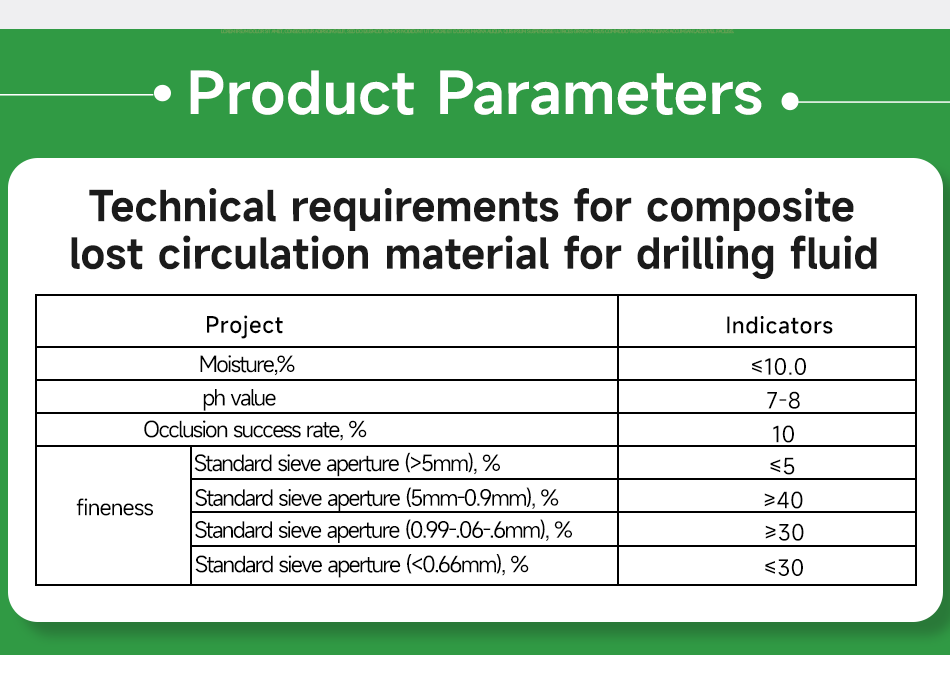

Technical Specifications of Composite lost circulation

| Item | Specification | |

| Moisture, % | ≤10.0 | |

pH Value 7–8 | 7-8 | |

| Sealing Success Rate, % 10 | 10 | |

Particle Size Distribution | Standard Sieve Opening (>5mm), % ≤ | ≤5 |

| Standard Sieve Opening (5mm-9mm), % ≥ | ≥40 | |

Standard Sieve Opening (0.9mm-0.6mm), % ≥ | ≥30 | |

| Standard Sieve Opening (<0.6mm), % ≤ | ≥30 | |

[Applications] It is suitable for sealing fractures and porous formations in drilling operations, and delivers enhanced performance when used in combination with other bridging materials.

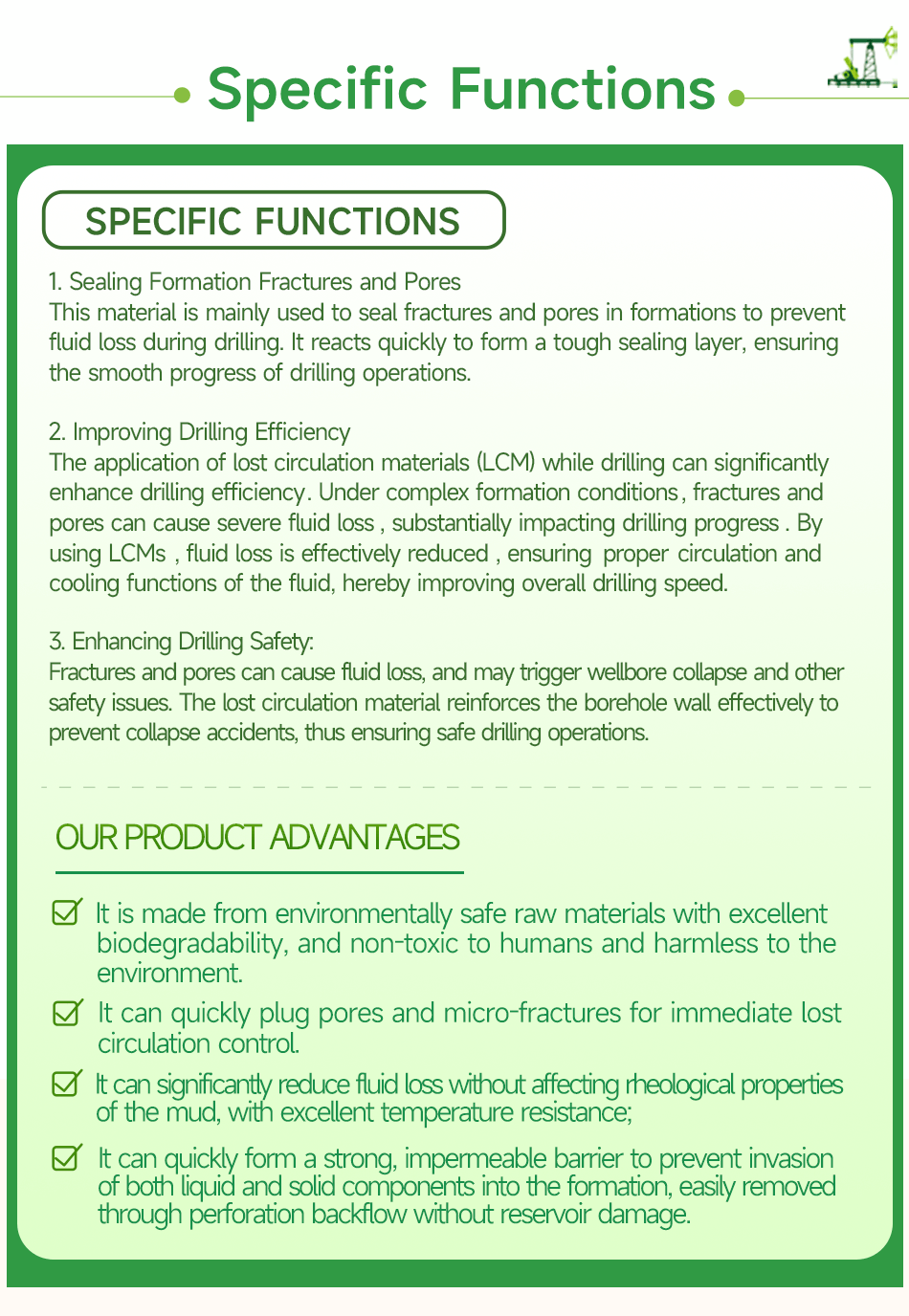

[Specific Functions]

1. It delivers rapid and effective sealing for pores and micro-fractures losses.

2. It quickly forms a strong impermeable sealing layer, which prevents liquid and solid phases in the working fluid from invading the reservoir, thereby avoiding reservoir damage. The sealing layer can be removed through perforation and backflushing.

3. It significantly reduces fluid loss without affecting rheological properties; excellent thermal resistance.

4. It is not affected by electrolyte contamination with non-toxic and harmlessness.

[Product Advantages]

1. It delivers measurable results within 30 minutes of application, significantly reducing drilling time and operational costs.

2. One-time sealing with long-lasting effect, low risk of recurring loss.

3. It is suitable for complex loss zones, various sizes of fractures and cavities, and can improve or replace conventional flush fluids.

4. It is directly added to mud circulation for sealing without compromising mud performance.

[Usage and Dosage]

1. For general seepage conditions:

Loss ≤2.4 m³/h: 1%–3%

Loss 2.4–15 m³/h: 2%–4%

Severe loss (no returns): 3%–5%, with a small amount of inert material if needed.

2. For reservoir protection during drilling:

Recommended dosage: 3.0%–5.0%.

[Packaging] 25 kg/bag in woven bags, in paper-plastic composite bags, or in bulk bags, or customizable according to client specifications.

[Storage Conditions] During storage and transport, store in a cool, ventilated, and dry warehouse. Keep away from fire, heat sources, and avoid direct sunlight.