[Appearance]

This product generally appears as colorless or yellow, free-flowing, uniform liquid.

[Physical and Chemical Properties]

Crude oil viscosity reducers are chemical agents used to lower the viscosity of heavy (high-viscosity) crude oil. By reducing flow resistance, they improve fluidity and enhance the efficiency of oil extraction and transportation. These agents are widely used in oil exploitation, transportation, and processing, particularly in heavy oil reservoirs where viscosity mitigation directly impacts producibility.

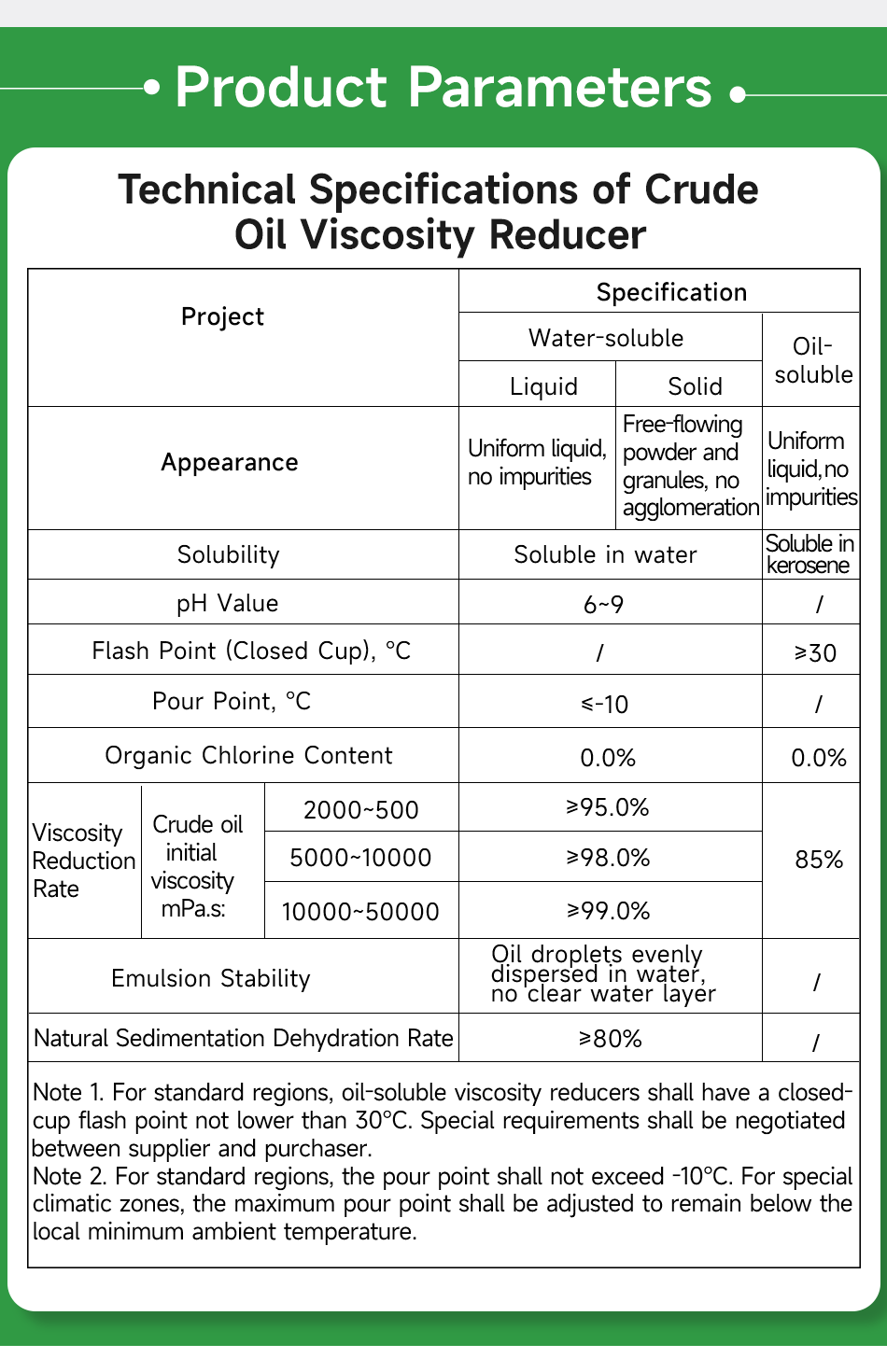

Technical Specifications of Crude Oil Viscosity Reducer

Item | Specification | ||||

| Water-soluble | Oil-soluble | ||||

| Liquid | Solid | ||||

| Appearance | Uniform liquid, no impurities | Free-flowing powder and granules, no agglomeration | Uniform liquid, no impurities | ||

| Solubility | Soluble in water | Soluble in kerosene | |||

| pH Value | 6-9 | - | |||

| Flash Point (Closed Cup), ℃ | / | ≥30 | |||

| Pour Point, ℃ | ≤-10 | / | |||

Organic Chlorine Content | 0.0% | 0.0% | |||

| Viscosity Reduction Rate | Crude oil initial viscosity mPa.s | 2000-500 | ≥95.0% | 85% | |

| 5000-10000 | ≥98.0% | ||||

| 10000-50000 | ≥99.0% | ||||

| Emulsion Stability | Oil droplets evenly dispersed in water, no clear water layer | / | |||

| Natural Sedimentation Dehydration Rate | ≥80% | / | |||

| Note 1. For standard regions, oil-soluble viscosity reducers shall have a closed-cup flash point not lower than 30°C. Special requirements shall be negotiated between supplier and purchaser. | |||||

| Note 2. For standard regions, the pour point shall not exceed -10°C. For special climatic zones, the maximum pour point shall be adjusted to remain below the local minimum ambient temperature. | |||||

[Applications]

Crude oil viscosity reducers are mainly used to lower the viscosity of crude oil and improve its fluidity, thereby enhancing extraction and gathering efficiency. By changing the oil’s viscosity, they reduce energy consumption and system pressure, improving recovery rates significantly while saving time and costs.

[Product Advantages]

1. Improve the coalescence of wax crystals and asphaltenes, enhancing crude oil mobility;

2. Reduce oil-water interfacial tension, effectively improving recovery;

3. Wide application range and simple operation;

4. Cost-effective and eco-friendly product.

[Usage and Dosage]

The product can be injected either statically or dynamically. The dosage should be adjusted based on actual oil well conditions such as temperature, viscosity, and water content. The recommended dosage is 20–40 kg per 1000 m³ of water. In crude oil applications, the effective concentration should be maintained at 50–100 ppm.

[Packaging]

Typically packaged in iron or plastic barrels of 1000kg (IBC tank), 200kg, or 25kg net weight. Custom packaging available upon request. Handle with care during transport; avoid collision and inversion.

[Storage Conditions]

Store in a dry, cool, and ventilated warehouse, away from fire and heat sources. Avoid skin or eye contact during handling and use. In case of contact, rinse immediately with plenty of water.