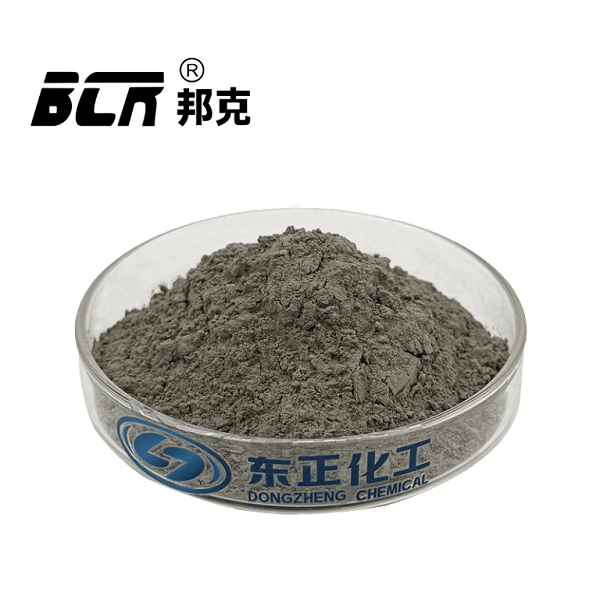

[Appearance] This product appears as gray or black powder or granules.

[Physical and Chemical Properties]

This product is non-toxic, odorless, and suitable for dry blending. It has no adverse effect on thickening time, rheological properties, or free water of the cement slurry. A notable increase in compressive strength is observed after addition. It is applicable to conventional and low-density cement slurries, as well as wells with irregular or enlarged boreholes. It is also suitable for pressure-balancing cementing in deep wells, anti-channeling operations, and high-pressure oil and gas wells.

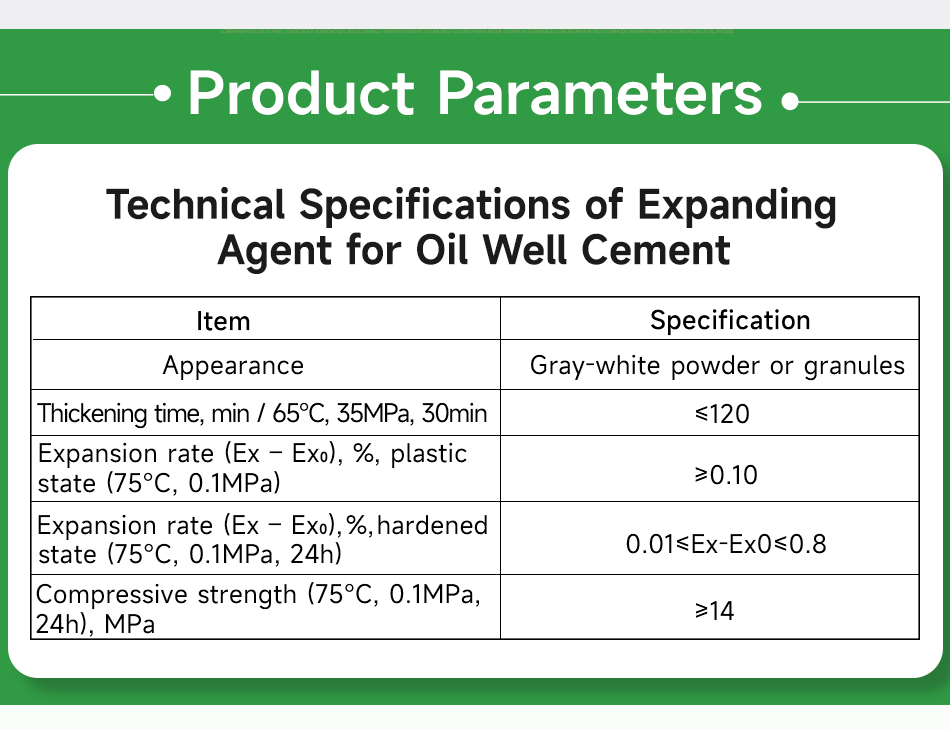

Technical Specifications of Expanding Agent for Oil Well Cement

| Item | Specification |

Appearance | Gray-white powder or granules |

| Thickening time, min / 65°C, 35MPa, 30min | ≤120 |

| Expansion rate (Ex – Ex₀), %, plastic state (75°C, 0.1MPa) | ≥0.10 |

| Expansion rate (Ex – Ex₀), %, hardened state (75°C, 0.1MPa, 24h) | 0.01 ≤ Ex–Ex₀ ≤ 0.8 |

Compressive strength (75°C, 0.1MPa, 24h), MPa | ≥14 |

[Application]

The main functions of oil well cement expanding agents include compensating for slurry shrinkage, enhancing cement stone strength, reducing permeability, and preventing channeling. By promoting the expansion of hydration product crystals, the expanding agent compensates for the slight volume shrinkage caused by slurry dehydration. It reduces the porosity of the cement stone and improves pore distribution, thereby increasing strength, lowering permeability, and preventing gas migration. The expanding agent also improves the interfacial bond strength between the cement stone and casing/formation, enhances cement sheath bonding, prevents corrosion of both the cement and casing, and helps control annular flow.

[Product Advantages]

1. Effectively improve the expansion performance of cement slurry;

2. Enhance the strength and corrosion resistance of cement;

3. Reduce the setting time of cement slurry;

4. Effectively improve insulation performance;

5. Adapt to various well conditions.

[Usage and Dosage] The typical dosage is 2%–3% by weight of cement (BWOC).

[Packaging] 25kg/bag, packed in triple-layer composite kraft paper bags; customized packaging available upon request.

[Storage Conditions] This product should be stored in a well-ventilated, dry area, away from moisture, fire, and high temperatures.