[Molecular Formula] C₇H₈O₂

[Molecular Weight] 124.13722

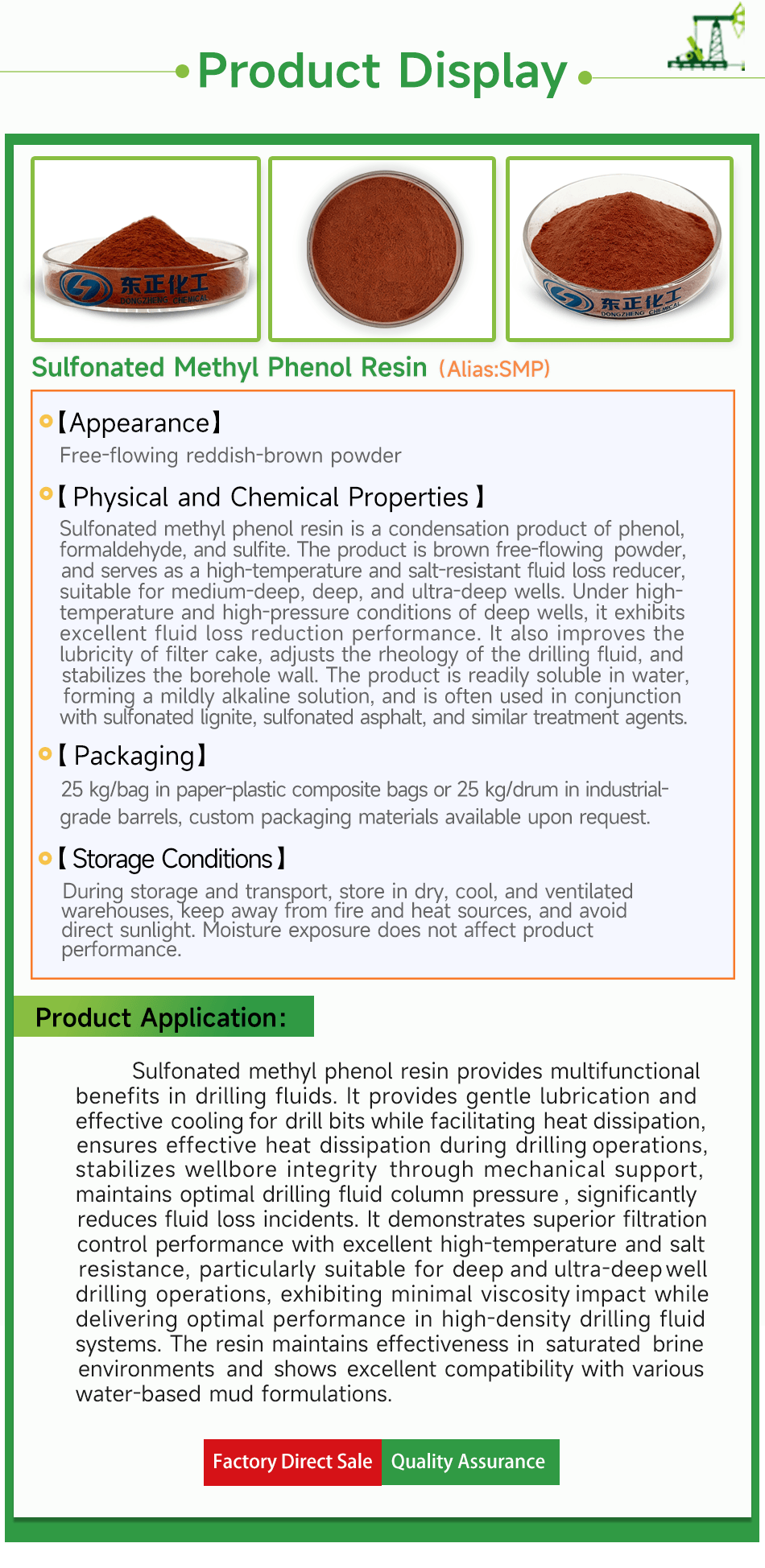

[Appearance] Free-flowing reddish-brown powder.

[Physical and Chemical Properties]

Sulfonated methyl phenol resin is a condensation product of phenol, formaldehyde, and sulfite. The product is brown free-flowing powder, and serves as a high-temperature and salt-resistant fluid loss reducer, suitable for medium-deep, deep, and ultra-deep wells. Under high-temperature and high-pressure conditions of deep wells, it exhibits excellent fluid loss reduction performance. It also improves the lubricity of filter cake, adjusts the rheology of the drilling fluid, and stabilizes the borehole wall. The product is readily soluble in water, forming a mildly alkaline solution, and is often used in conjunction with sulfonated lignite, sulfonated asphalt, and similar treatment agents.

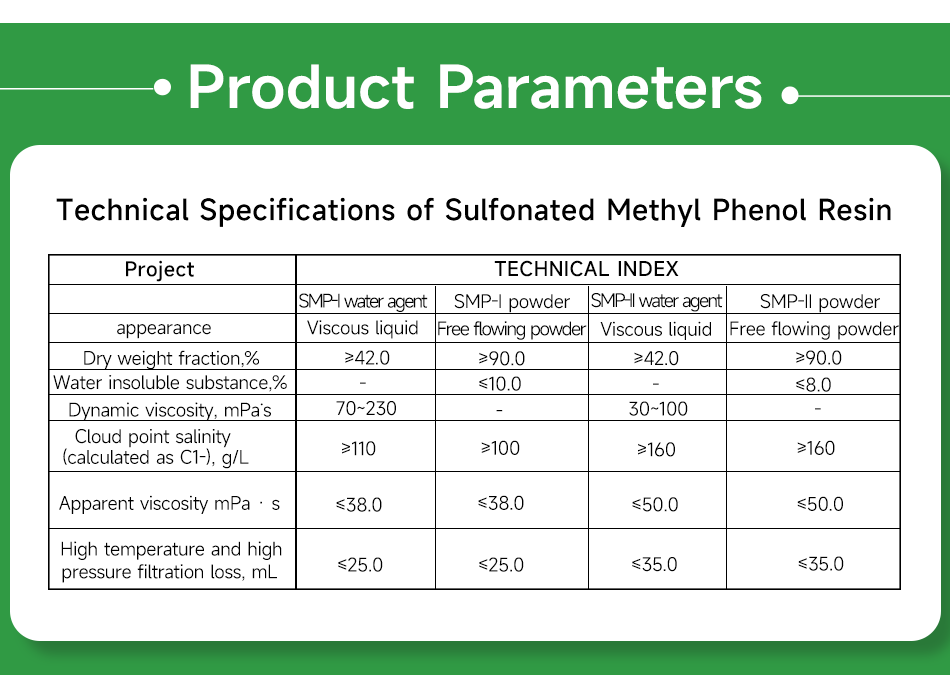

Technical Specifications of Sulfonated Methyl Phenol Resin

| Item | Specification | |||

SMP-ⅠAqueous Solution | SMP-ⅠPowder | SMP-Ⅱ Aqueous Solution | SMP-Ⅱ Powder | |

| Appearance | Viscous liquid | Free-flowing powder | Viscous liquid | Free-flowing powder |

| Solid content (dry basis), % | ≥42.0 | ≥90.0 | ≥42.0 | ≥90.0 |

| Water insoluble matter, % | - | ≤10.0 | - | ≤8.0 |

| Dynamic viscosity, mPa·s | 70-230 | - | 30-100 | - |

| Cloud point salinity (as Cl⁻), g/L | ≥110 | ≥100 | ≥160 | ≥160 |

| Apparent viscosity, mPa·s | ≤38.0 | ≤38.0 | ≤50.0 | ≤50.0 |

| HTHP fluid loss, mL | ≤25.0 | ≤25.0 | ≤35.0 | ≤35.0 |

[Applications]

Sulfonated methyl phenol resin provides multifunctional benefits in drilling fluids. It provides gentle lubrication and effective cooling for drill bits while facilitating heat dissipation, ensures effective heat dissipation during drilling operations, stabilizes wellbore integrity through mechanical support, maintains optimal drilling fluid column pressure, significantly reduces fluid loss incidents. It demonstrates superior filtration control performance with excellent high-temperature and salt resistance, particularly suitable for deep and ultra-deep well drilling operations, exhibiting minimal viscosity impact while delivering optimal performance in high-density drilling fluid systems. The resin maintains effectiveness in saturated brine environments and shows excellent compatibility with various water-based mud formulations.

[Specific Functions]

1. Viscosity Enhancement

SMP can increase the viscosity and consistency of drilling fluid, thereby reducing phase separation and maintaining the stability of the fluid.

2. High-temperature resistance improvement

SMP exhibits excellent high-temperature resistance, effectively maintaining drilling fluid performance under elevated temperature conditions and preventing thermal degradation of fluid properties.

3. Contaminant accumulation suppression

SMP also inhibits the deposition of contaminants in the drilling fluid, keeping the fluid clean and stable.

[Product Advantages]

1. Low dosage with excellent performance;

2. Outstanding resistance to high temperature and salinity;

3. Forms a thin and tough filter cake on borehole walls with good anti-collapse and wall-stabilizing lubricity;

4. User-friendly application, available in both liquid and powder forms per customer requirements.

[Usage and Dosage]

Add powder directly through hopper; recommended dosage is 0.5%–1%. Add liquid product directly into the mud; recommended dosage is 2%–4%.

[Packaging]

25 kg/bag in paper-plastic composite bags or 25 kg/drum in industrial-grade barrels, custom packaging materials available upon request.

[Storage Conditions]

During storage and transport, store in dry, cool, and ventilated warehouses, keep away from fire and heat sources, and avoid direct sunlight. Moisture exposure does not affect product performance.