[Molecular Formula] C

[Molecular Weight] 12.01

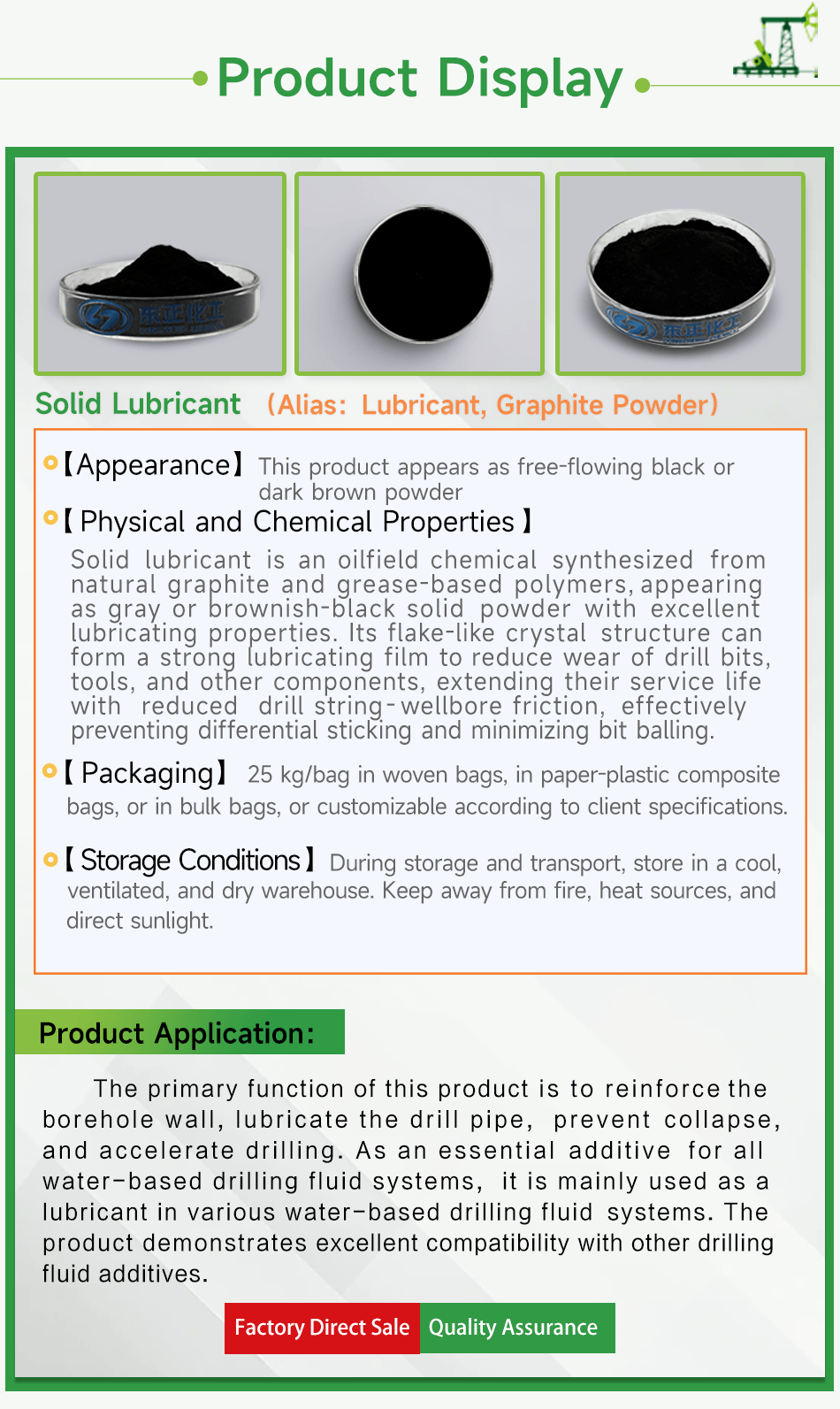

[Appearance] This product appears as free-flowing black or dark brown powder

[Physical and Chemical Properties]

Solid lubricant is an oilfield chemical synthesized from natural graphite and grease-based polymers, appearing as gray or brownish-black solid powder with excellent lubricating properties. Its flake-like crystal structure can form a strong lubricating film to reduce wear of drill bits, tools, and other components, extending their service life with reduced drill string-wellbore friction, effectively preventing differential sticking and minimizing bit balling.

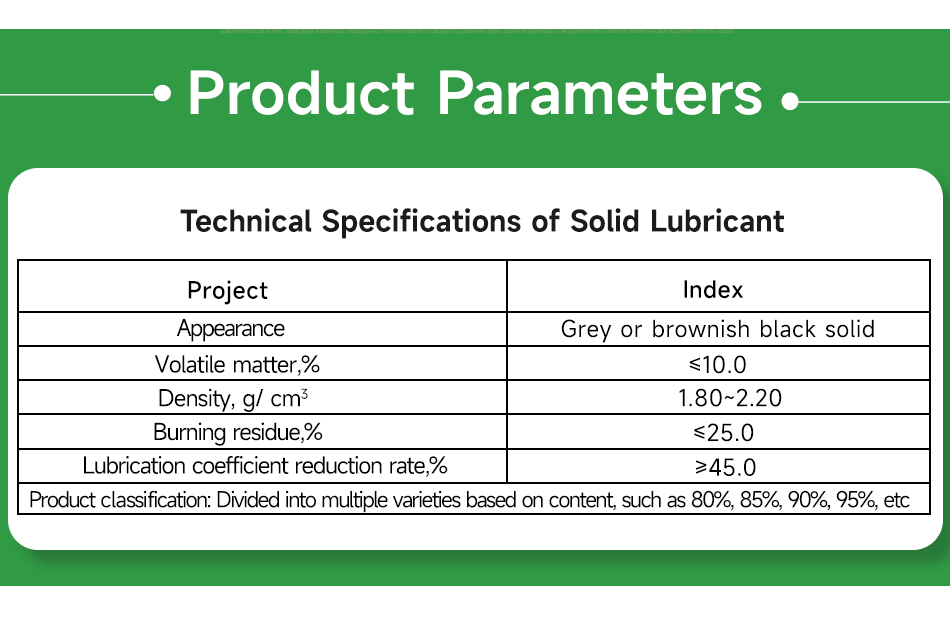

Technical Specifications of Solid Lubricant

| Item | Specification |

| Appearance | Gray or dark brown solid |

Volatile Matter, % ≤ | 10.0 |

| Density, g/cm³ | 1.80-2.20 |

| Ash Content, % ≤ | 25.0 |

| Lubrication Coefficient Reduction Rate, % ≥ | 45.0 |

| Product Classification: Available in multiple grades based on content, including 80%, 85%, 90%, and 95%. | |

[Applications]

The primary function of this product is to reinforce the borehole wall, lubricate the drill pipe, prevent collapse, and accelerate drilling. As an essential additive for all water-based drilling fluid systems, it is mainly used as a lubricant in various water-based drilling fluid systems. The product demonstrates excellent compatibility with other drilling fluid additives.

[Specific Functions]

1. Improve Drill Bit Efficiency and Extend Service Life:

Graphite powder forms a black coating in drilling fluid, filling the capillary pores of the drill bit surface, providing lubrication, reducing contact area with the borehole wall, and lowering friction, thus enhancing drilling efficiency and bit lifespan.

2. Reduce Mud Sticking and Bit Balling:

During drilling operations, as the borehole depth increases, rising wellbore pressure can lead to mud-induced bit balling. Adding graphite solid lubricant forms a protective, low-friction coating on both the drill bit and wellbore surfaces that prevents mud adhesion and minimizes balling incidents.

3. Reduce Drilling Time and Cost:

Graphite lubricant improves drilling efficiency, thereby reducing overall drilling time and cost.

4. Improve Filter Cake Lubricity:

Graphite powder improves the lubricity of the filter cake, reducing friction between drilling tools and the borehole wall, lowering lifting resistance and preventing sticking accidents.

5. Prevente Collapse and Reinforce Borehole Wall:

Graphite powder not only acts as a lubricant in drilling fluid, but also strengthens the borehole wall and prevents collapse, ensuring smooth drilling operations.

[Product Advantages]

1. Excellent lubricating performance;

2. No adverse impact on drilling fluid properties;

3. Outstanding high-temperature resistance;

4. Excellent compatibility and user-friendly application;

5. Non-toxic, harmless, and environmentally non-polluting.

[Usage and Dosage]

The solid lubricant can be directly added to drilling fluid; recommended dosage is 2%–3%.

[Packaging] 25 kg/bag in woven bags, in paper-plastic composite bags, or in bulk bags, or customizable according to client specifications.

[Storage Conditions] During storage and transport, store in a cool, ventilated, and dry warehouse. Keep away from fire, heat sources, and direct sunlight.