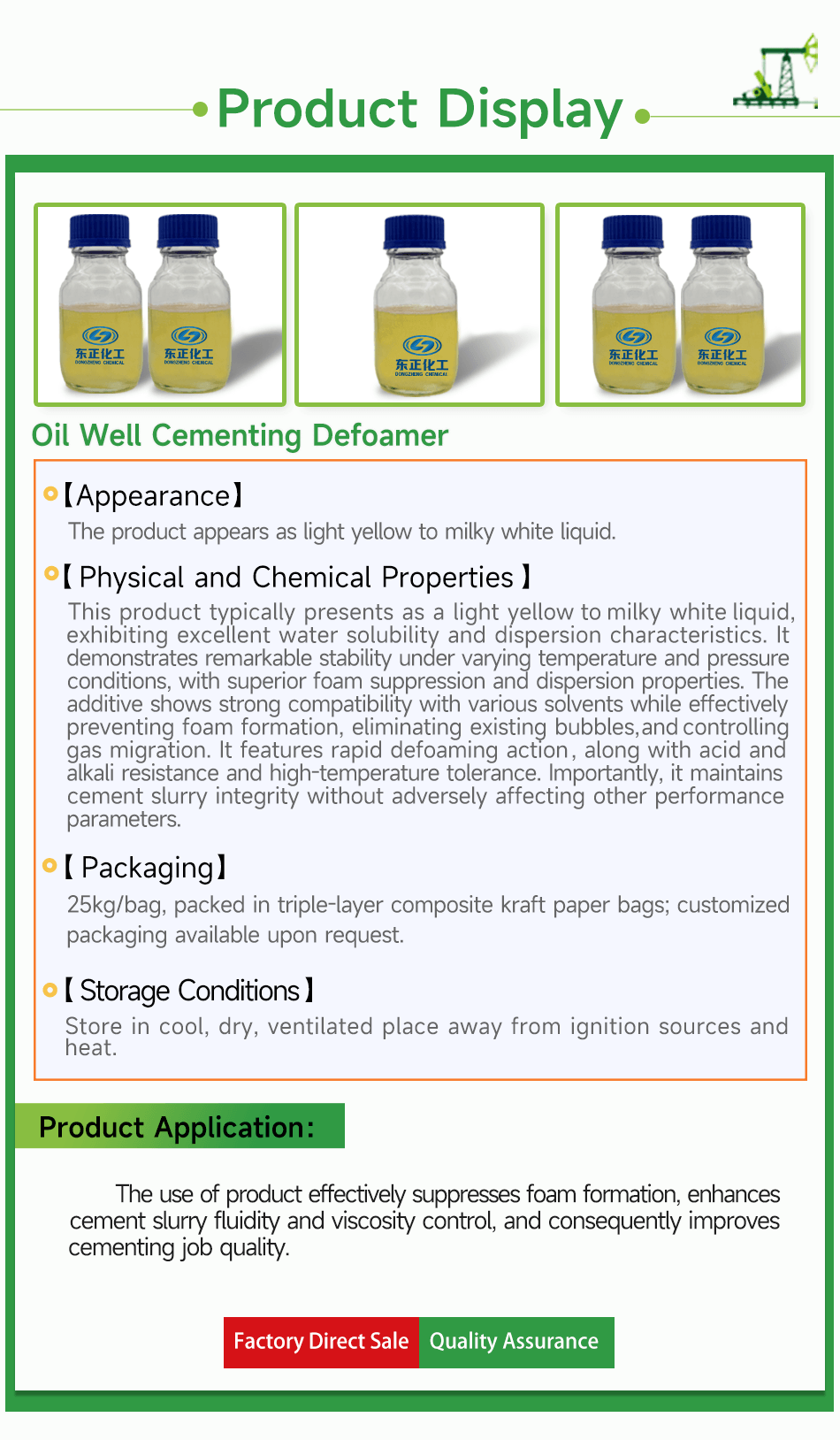

[Appearance] The product appears as light yellow to milky white liquid.

[Physical and Chemical Properties]

This product typically presents as a light yellow to milky white homogeneous liquid, exhibiting excellent water solubility and dispersion characteristics. It demonstrates remarkable stability under varying temperature and pressure conditions, with superior foam suppression and dispersion properties. The additive shows strong compatibility with various solvents while effectively preventing foam formation, eliminating existing bubbles, and controlling gas migration. It features rapid defoaming action, along with acid and alkali resistance and high-temperature tolerance. Importantly, it maintains cement slurry integrity without adversely affecting other performance parameters.

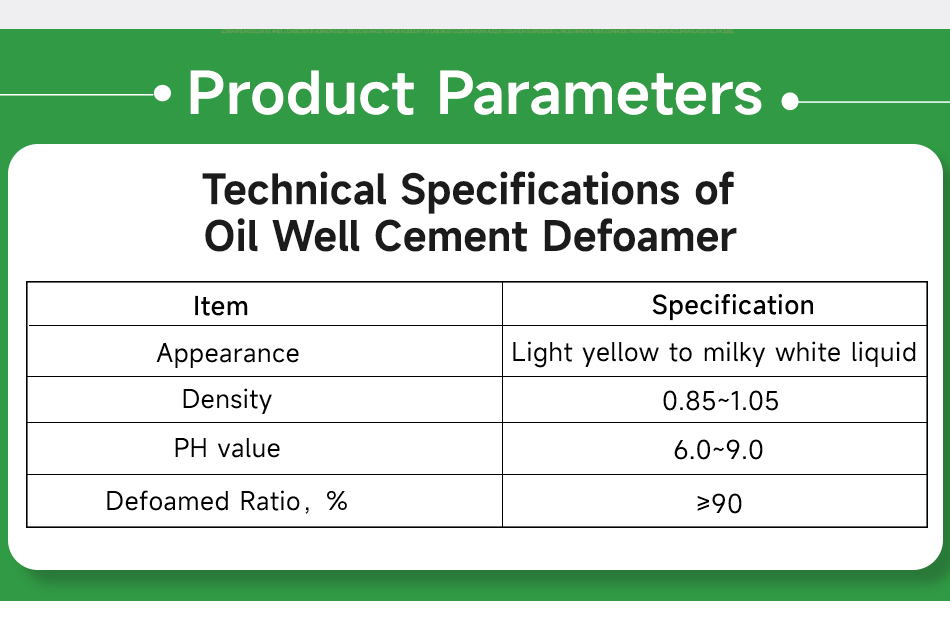

Technical Specifications of Oil Well Cement Defoamer

| Item | Specification |

| Appearance | Light yellow to milky white liquid |

| Density | 0.85-1.05 |

| PH value | 6.0-9.0 |

| Defoamed Ratio,% | ≥90 |

[Application]

The use of product effectively suppresses foam formation, enhances cement slurry fluidity and viscosity control, and consequently improves cementing job quality.

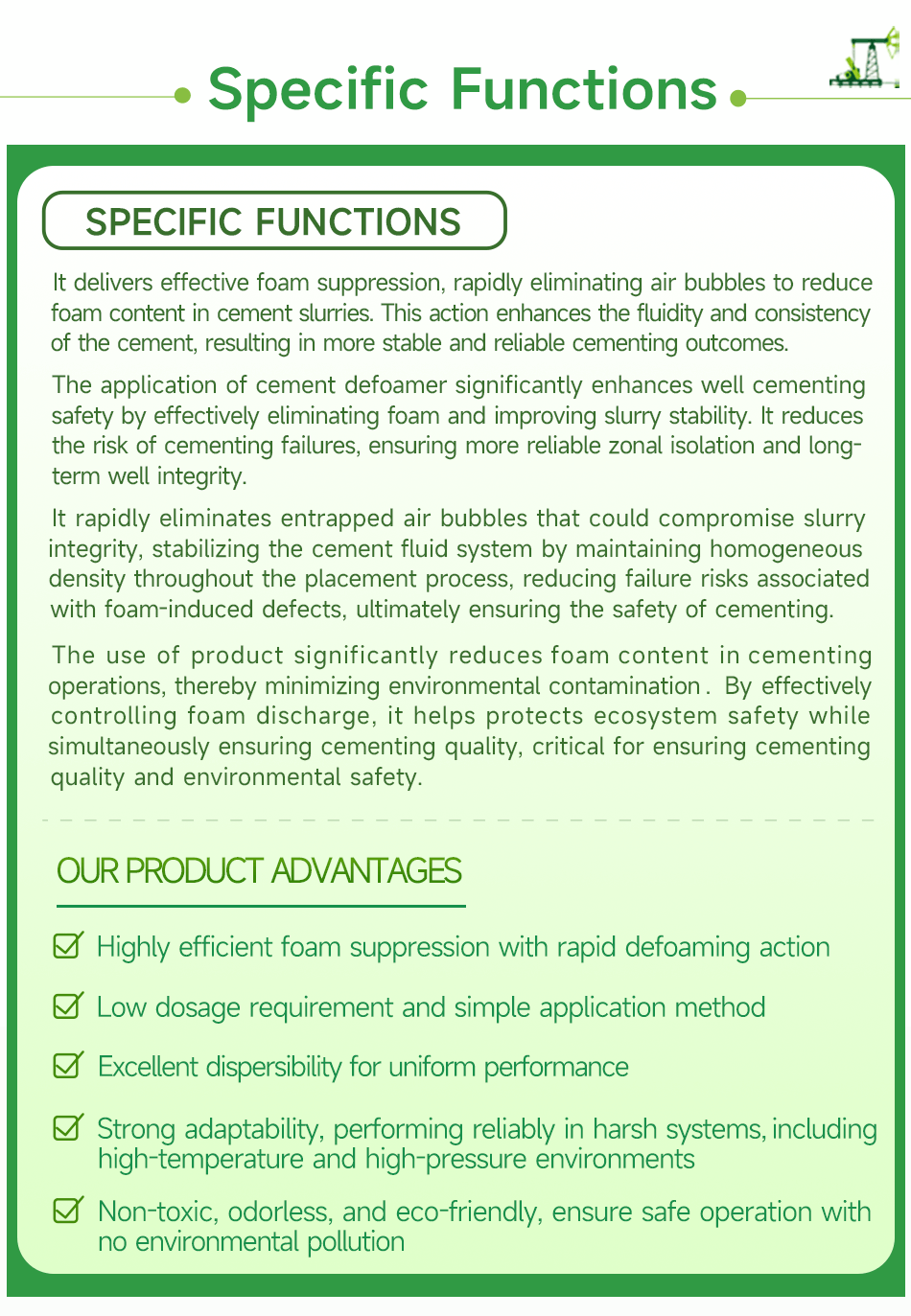

1. It delivers effective foam suppression, rapidly eliminating air bubbles to reduce foam content in cement slurries. This action enhances the fluidity and consistency of the cement, resulting in more stable and reliable cementing outcomes.

2. The application of cement defoamer significantly enhances well cementing safety by effectively eliminating foam and improving slurry stability. It reduces the risk of cementing failures, ensuring more reliable zonal isolation and long-term well integrity.

3. It rapidly eliminates entrapped air bubbles that could compromise slurry integrity, stabilizing the cement fluid system by maintaining homogeneous density throughout the placement process, reducing failure risks associated with foam-induced defects, ultimately ensuring the safety of cementing.

4. The use of product significantly reduces foam content in cementing operations, thereby minimizing environmental contamination. By effectively controlling foam discharge, it helps protects ecosystem safety while simultaneously ensuring cementing quality, critical for ensuring cementing quality and environmental safety.

[Product Advantages]

1. Highly efficient foam suppression with rapid defoaming action;

2. Low dosage requirement and simple application method;

3. Excellent dispersibility for uniform performance;

4. Strong adaptability, performing reliably in harsh systems, including high-temperature and high-pressure environments;

5. Non-toxic, odorless, and eco-friendly, ensure safe operation with no environmental pollution.

[Usage and Dosage] The typical dosage is 0.5%–3% by weight of cement (BWOC).

[Packaging] 25kg/bag, packed in triple-layer composite kraft paper bags; customized packaging available upon request.

[Storage Conditions] Store in cool, dry, ventilated place away from ignition sources and heat.