[Molecular Formula] HOCH₂CH(OH)CH₂OH

[Molecular Weight] 92.90

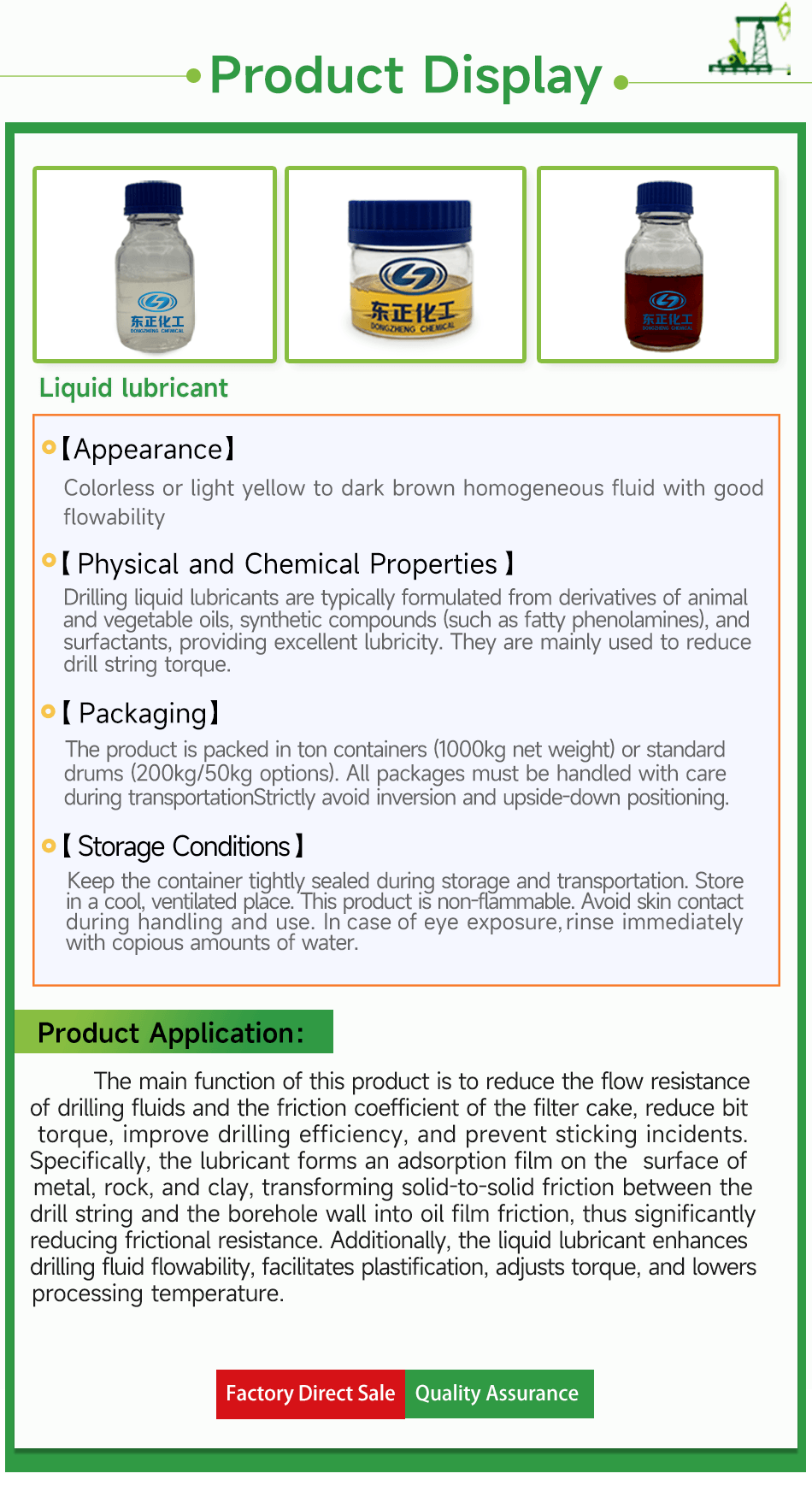

[Appearance] Colorless or light yellow to dark brown homogeneous fluid with good flowability.

[Physical and Chemical Properties] Drilling liquid lubricants are typically formulated from derivatives of animal and vegetable oils, synthetic compounds (such as fatty phenolamines), and surfactants, providing excellent lubricity. They are mainly used to reduce drill string torque.

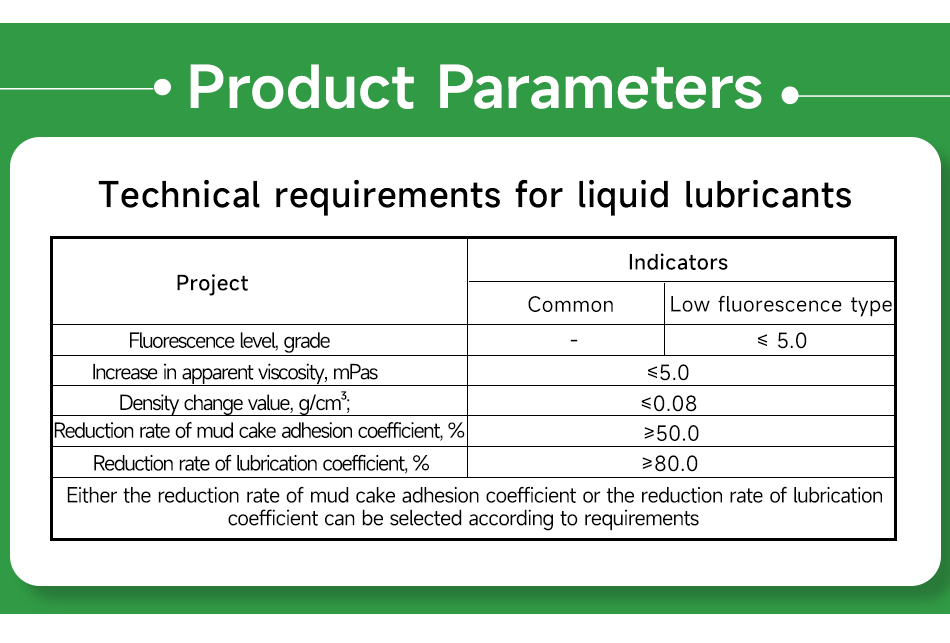

Technical Specifications of Liquid Lubricants

| Item | Specification | |

| Ordinary Type | Low-fluorescence | |

| Fluorescence Grade, Level | - | ≤ 5.0 |

| Apparent Viscosity Increase, mPa·s | ≤ 5.0 | |

| Density Variation, g/cm³ | ≤ 0.08 | |

| Filter Cake Adhesion Coefficient Reduction, % | ≥ 50.0 | |

| Lubrication Coefficient | ≥ 80.0 | |

| The reduction rate of mud cake adhesion coefficient or the reduction rate of lubricity coefficient may be selected as required. | ||

[Applications]

The main function of this product is to reduce the flow resistance of drilling fluids and the friction coefficient of the filter cake, reduce bit torque, improve drilling efficiency, and prevent sticking incidents. Specifically, the lubricant forms an adsorption film on the surface of metal, rock, and clay, transforming solid-to-solid friction between the drill string and the borehole wall into oil film friction, thus significantly reducing frictional resistance. Additionally, the liquid lubricant enhances drilling fluid flowability, facilitates plastification, adjusts torque, and lowers processing temperature.

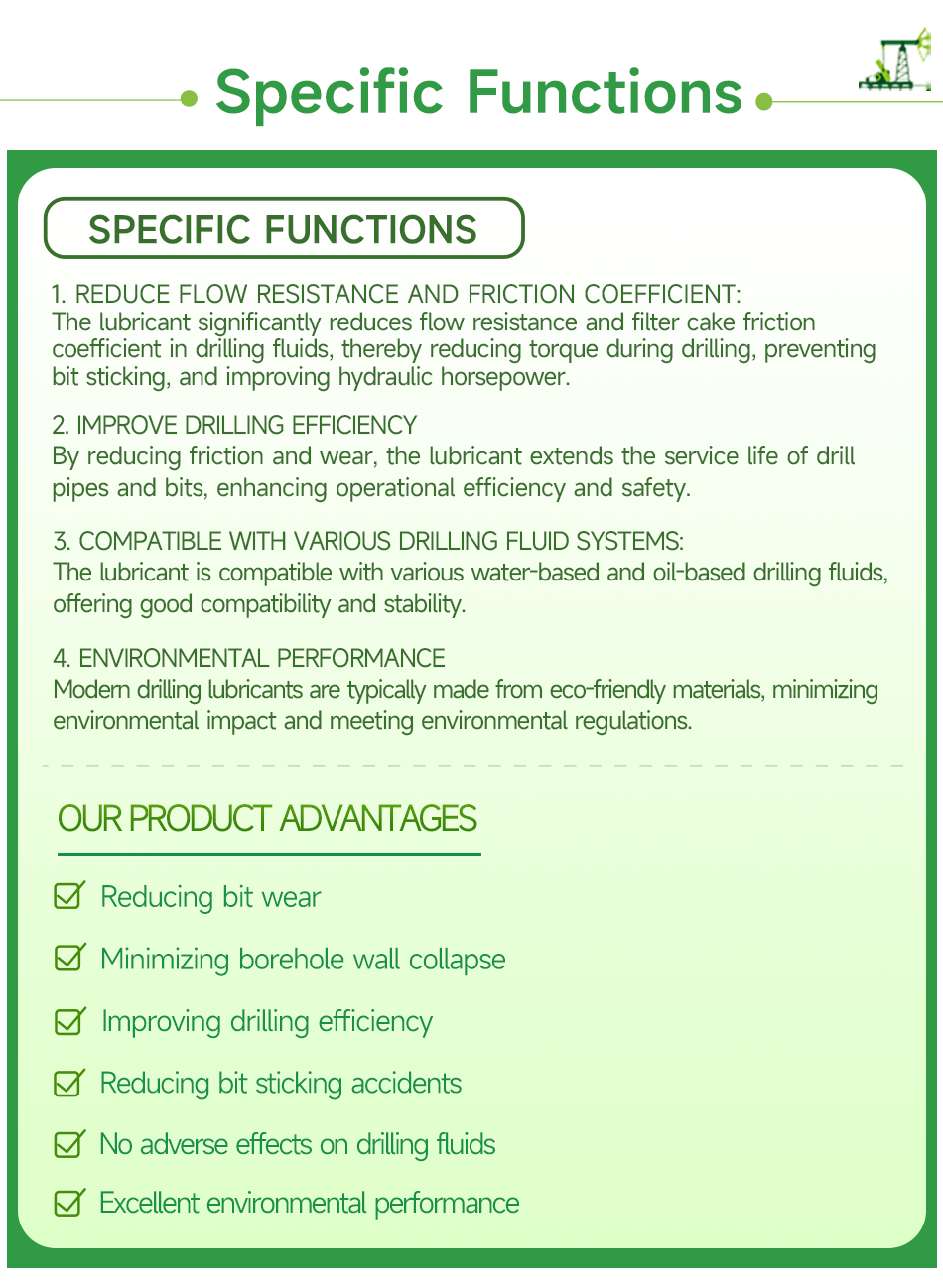

[Specific Functions]

1. Reduce Flow Resistance and Friction Coefficient

The lubricant significantly reduces flow resistance and filter cake friction coefficient in drilling fluids, thereby reducing torque during drilling, preventing bit sticking, and improving hydraulic horsepower.

2. Improve Drilling Efficiency

By reducing friction and wear, the lubricant extends the service life of drill pipes and bits, enhancing operational efficiency and safety.

3. Compatible with Various Drilling Fluid Systems

The lubricant is compatible with various water-based and oil-based drilling fluids, offering good compatibility and stability.

4. Environmental Performance

Modern drilling lubricants are typically made from eco-friendly materials, minimizing environmental impact and meeting environmental regulations.

[Product Advantages]

1. Reducing bit wear;

2. Minimizing borehole wall collapse;

3. Improving drilling efficiency;

4. Reducing bit sticking accidents;

5. No adverse effects on drilling fluids;

6. Excellent environmental performance.

[Usage and Dosage]

Liquid lubricant can be directly added to the drilling fluid, with a recommended dosage of 1%–3%.

[Packaging] The product is packed in ton containers (1000kg net weight) or standard drums (200kg/50kg options). All packages must be handled with care during transportation

Strictly avoid inversion and upside-down positioning.

[Storage Conditions] Keep the container tightly sealed during storage and transportation. Store in a cool, ventilated place. This product is non-flammable. Avoid skin contact during handling and use. In case of eye exposure, rinse immediately with copious amounts of water.