[Chemical Structure] C₇H₈O₂

[Molecular Weight] 124.13722

[Appearance] This product appears as white or light gray powder or granule.

[Physical and Chemical Properties]

This product is modified through polymerization of AMPS, low-molecular-weight amides, and polyhydroxy carboxylic acids. It is a free-flowing powder or fine granule.Temperature resistance: 30–200°C.Salt resistance: From freshwater to saturated brine.Fluid loss performance: API fluid loss ≤ 100 ml.Water solubility: Easily soluble in water.

This product is compatible with other additives and is suitable for all classes of oil well cement. When applied, it shows minimal free fluid (approaching zero), exhibits a short thickening transition time with near-right-angle thickening behavior, and maintains excellent slurry stability. It is applicable to low-density, conventional-density, and high-density cement slurry systems and exhibits a slight retarding effect.

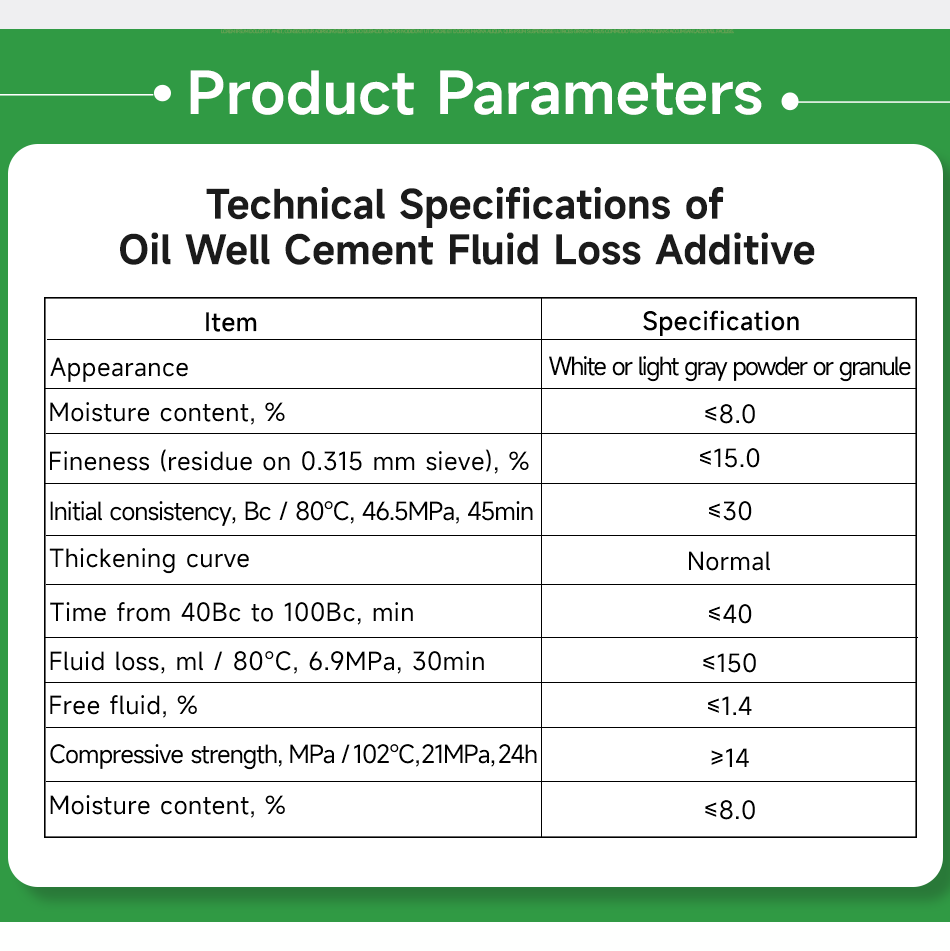

Technical Specifications of Oil Well Cement Fluid Loss Additive

| Item | Specification |

| Appearance | White or light gray powder or granule |

| Moisture content, % | ≤8.0 |

| Fineness (residue on 0.315 mm sieve), % | ≤15.0 |

| Initial consistency, Bc / 80°C, 46.5MPa, 45min | ≤30 |

| Thickening curve | Normal |

| Time from 40Bc to 100Bc, min | ≤40 |

| Fluid loss, ml / 80°C, 6.9MPa, 30min | ≤150 |

| Free fluid, % | ≤1.4 |

| Compressive strength, MPa / 102°C, 21MPa, 24h | ≥14 |

| Moisture, % | ≤8.0 |

[Application] The primary function of this fluid loss additive is to reduce fluid loss, prevent fluid channeling, and enhance high-temperature resistance and salt resistance. Specifically, by reducing the fluid loss of the cement slurry and its penetration into the wellbore wall, it helps prevent oil, gas, and water channeling, thereby improving the cementing quality. It also enhances the slurry’s resistance to temperature and salinity, making it suitable for various well conditions such as shallow gas wells, high-pressure gas wells, and directional wells.

[Product Advantages]

1. Significantly reduce the fluid loss of cement slurry;

2. Offer high resistance to temperature and salinity;

3. Effectively improve the compressive strength of the cement sheath;

4. Prevent fluid migration;

5. Wide application range and good compatibility with other additives.

[Usage and Dosage] Recommended dosage is 1% to 3% by weight of cement (BWOC).

[Packaging] 25kg per bag, packed in triple-layer composite kraft paper sacks; customizable packaging is also available.

[Storage Conditions] This product should be stored in a ventilated, dry area, away from moisture, fire, and high temperatures.