[Molecular Formula] CH₃₁₇(CH₂)(CH₃)₃NI

[Molecular Weight] 439.5011

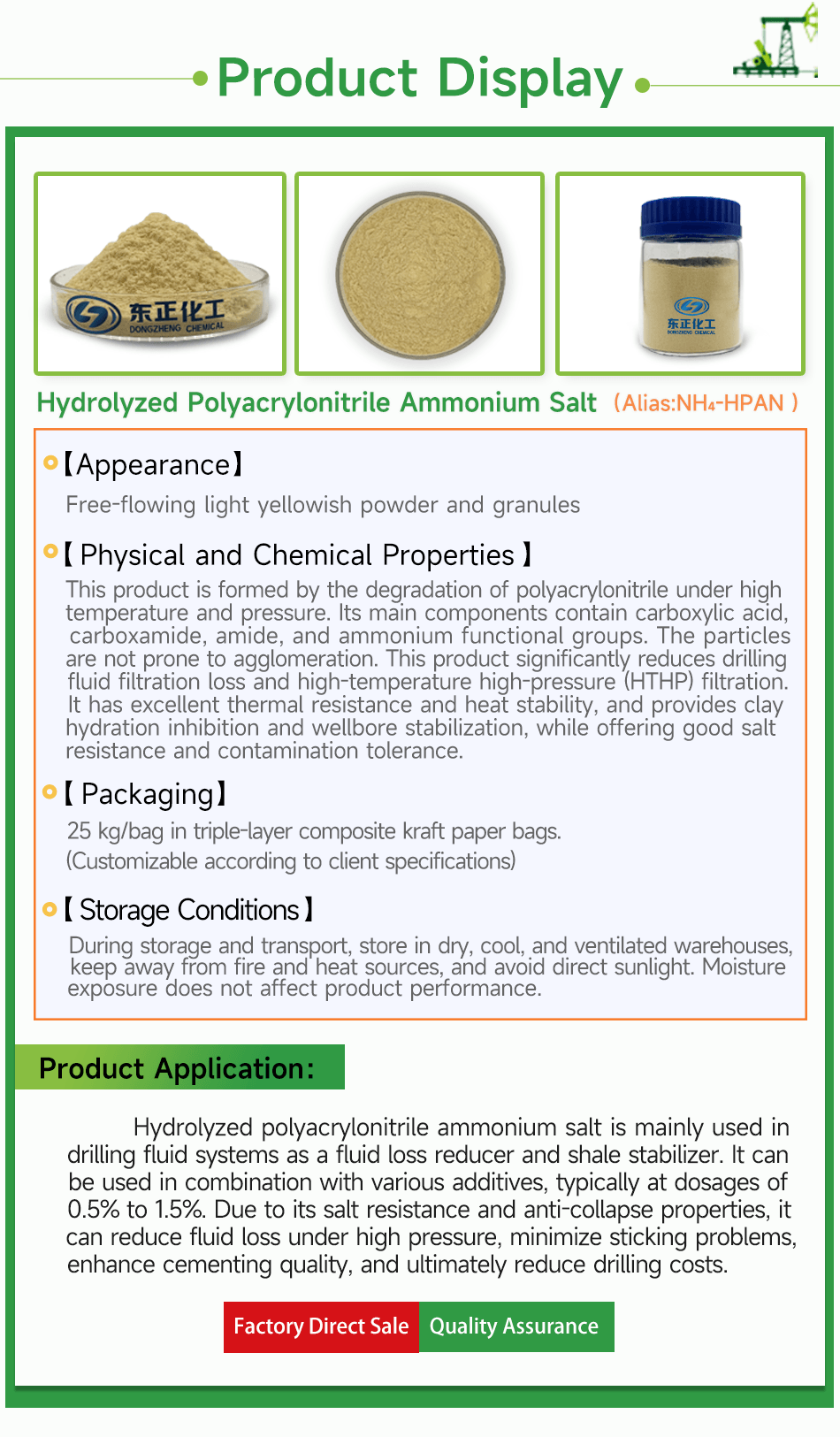

[Appearance] Free-flowing light yellowish powder and granules

[Physical and Chemical Properties]

This product is formed by the degradation of polyacrylonitrile under high temperature and pressure. Its main components contain carboxylic acid, carboxamide, amide, and ammonium functional groups. The particles are not prone to agglomeration. This product significantly reduces drilling fluid filtration loss and high-temperature high-pressure (HTHP) filtration. It has excellent thermal resistance and heat stability, and provides clay hydration inhibition and wellbore stabilization, while offering good salt resistance and contamination tolerance.

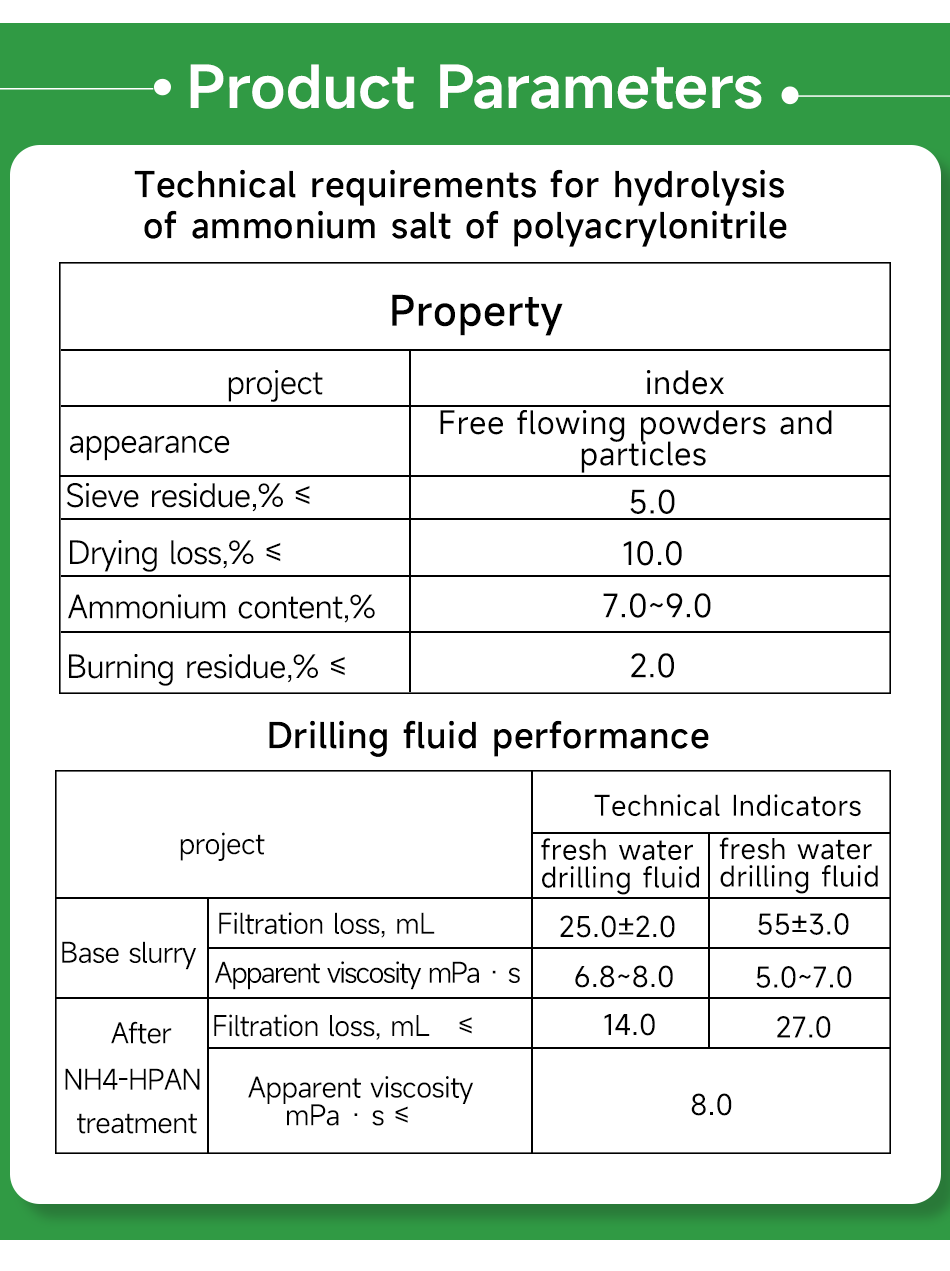

Technical Specifications of Hydrolyzed Polyacrylonitrile Ammonium Salt

| Physicochemical Performance | |||

| Item | Specification | ||

| Appearance | Free-flowing powder and granules | ||

| Residue on sieve, % ≤ | 5.0 | ||

Loss on drying, % ≤ | 10.0 | ||

| Ammonium content, % | 7.0-9.0 | ||

| Ash content, % ≤ | 2.0 | ||

| Drilling Fluid Properties | |||

| Item | Specification | ||

| Freshwater Drilling Fluid | Brine Drilling Fluid | ||

Base Slurry | Fluid Loss, mL | 25.0±2.0 | 55.0±3.0 |

Apparent viscosity, mPa·s | 6.8-8.0 | 5.0-7.0 | |

| Following afterNH₄-HPAN treatment | Fluid Loss, mL ≤ | 14.0 | 27.0 |

| Apparent viscosity, mPa·s ≤ | 8.0 | ||

[Applications]

Hydrolyzed polyacrylonitrile ammonium salt is mainly used in drilling fluid systems as a fluid loss reducer and shale stabilizer. It can be used in combination with various additives, typically at dosages of 0.5% to 1.5%. Due to its salt resistance and anti-collapse properties, it can reduce fluid loss under high pressure, minimize sticking problems, enhance cementing quality, and ultimately reduce drilling costs.

[Specific Functions]

1. Fluid loss reduction

The ammonium salt can significantly reduce fluid loss, especially under high-temperature and high-pressure conditions, where their effectiveness is markedly enhanced. This reduction in fluid loss helps minimize liquid loss during drilling operations, thereby stabilizing wellbore walls and preventing formation collapse.

2. Anti-Collapse Effect

Due to its embedding effect in shale, the ammonium salt provides a certain degree of borehole stabilization. In high-salinity formations, it effectively prevents wellbore collapse, ensuring borehole integrity.

3. Salt Resistance

Ammonium salts have strong salt tolerance and remain stable in high-salinity environments, without efficacy loss despite increasing salinity levels. This characteristic makes them particularly critical for high-salt formation treatment.

4. Viscosity Reduction

Some ammonium salt products also reduce fluid viscosity, thereby minimizing complications during drilling operations.

5. Hydration Enhancement

By introducing sulfonate groups, the ammonium salt enhances its hydration ability, with strong water-binding energy, further strengthening the wellbore, and preventing collapse and sticking.

[Product Advantages]

1. Strong inhibition with effective borehole stabilization;

2. Environmentally compliant: Non-toxic and pollution-free

3. Effective fluid loss control and improved filter cake quality;

4. Superior compatibility and user-friendly application

[Usage and Dosage]

Recommended dosage: 0.5%–1.5%.

[Packaging]

25 kg/bag in triple-layer composite kraft paper bags. (Customizable according to client specifications).

[Storage Conditions]

During storage and transport, store in dry, cool, and ventilated warehouses, keep away from fire and heat sources, and avoid direct sunlight. Moisture exposure does not affect product performance.