[Structural Formula] N(CH₂CH₂OH)₃

[Molecular Weight] 181.23092

[Physical and Chemical Properties] This product comprises inorganic strength-enhancing materials that significantly improve early-stage compressive strength of set cement while maintaining uncompromised long-term strength development.Applicable for oil and gas wells with a bottom hole circulating temperature (BHCT) of 30℃–90℃.It can effectively shorten the thickening time of cement slurry and enhance early compressive strength.

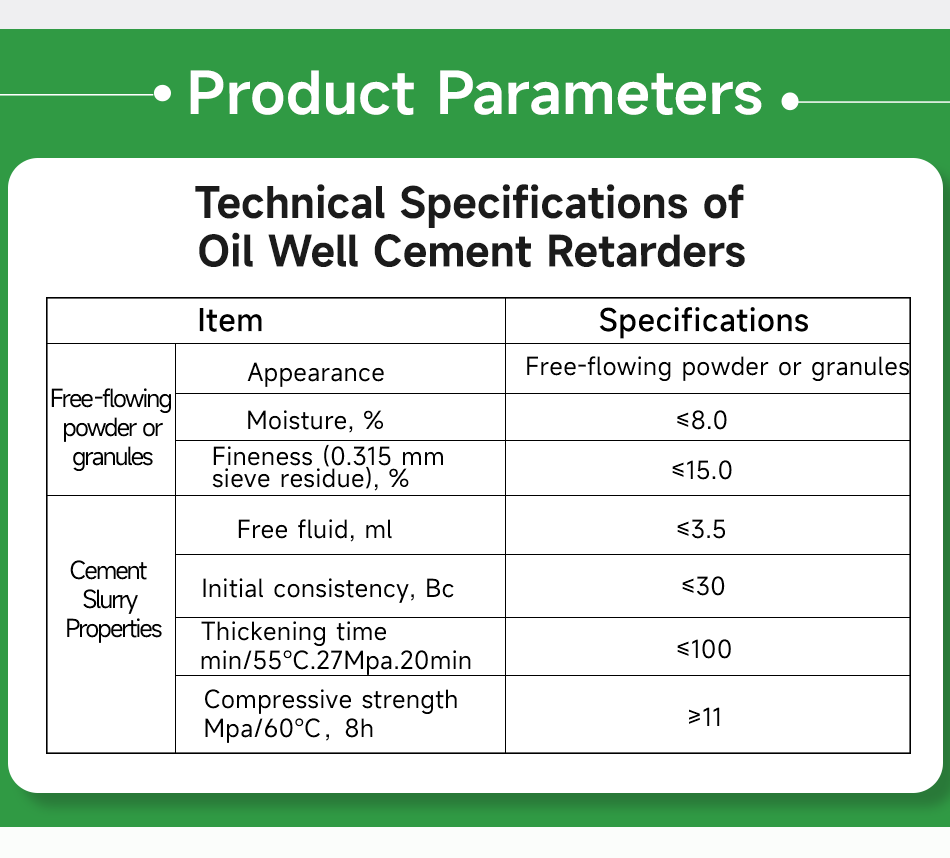

Technical Specifications of Accelerator for Oil Well Cement

| Item | Specifications | |

| Physical and Chemical Properties | Appearance | Free-flowing powder or granules |

| Moisture, % | ≤8.0 | |

Fineness (0.315 mm sieve residue), % | ≤15.0 | |

| Cement Slurry Properties | Free fluid, ml | ≤3.5 |

Initial consistency, Bc | ≤30 | |

| Thickening time, min / 55℃, 27MPa, 20min | ≤100 | |

| Compressive strength, MPa / 60℃, 8h | ≥11 | |

[Application] The primary function of cement accelerators is to accelerate the hydration reaction of cement and shorten the thickening time of the slurry, thereby speeding up cement setting and hardening. Accelerators significantly reduce the waiting-on-cement (WOC) time and enhance early strength, which is critical for oil well cementing operations.

[Specific Functions]

1. Accelerate cement hydration. The accelerator enhances the hydration process, allowing cement to set and harden more rapidly.

2. Reduce waiting-on-cement time. In cementing operations, the accelerator significantly shortens the WOC time, enabling completion within 6 to 8 hours and speeding up overall project progress.

3. Increase early strength. The accelerator improves the early compressive strength of the set cement, ensuring adequate strength in a short time and enhancing wellbore stability.

[Product Advantages]

1. Shorten waiting-on-cement time;

2. Increase early strength;

3. Improve rheological properties;

4. Features broad applicability and excellent compatibility with other cement additives.

[Usage and Dosage] Recommended dosage: 1%–4% (by weight of cement, BWOC).

[Packaging] 25kg/bag, packed in moisture-proof kraft paper bags with triple-layer composite structure.

[Storage Conditions] The product should be stored in a dry, well-ventilated area, protected from moisture, fire, and high temperatures, and kept away from acidic substances.