Molecular Formula: [C6H7O2(OH)2OCH2COONa]n

Molecular Weight: 264.204

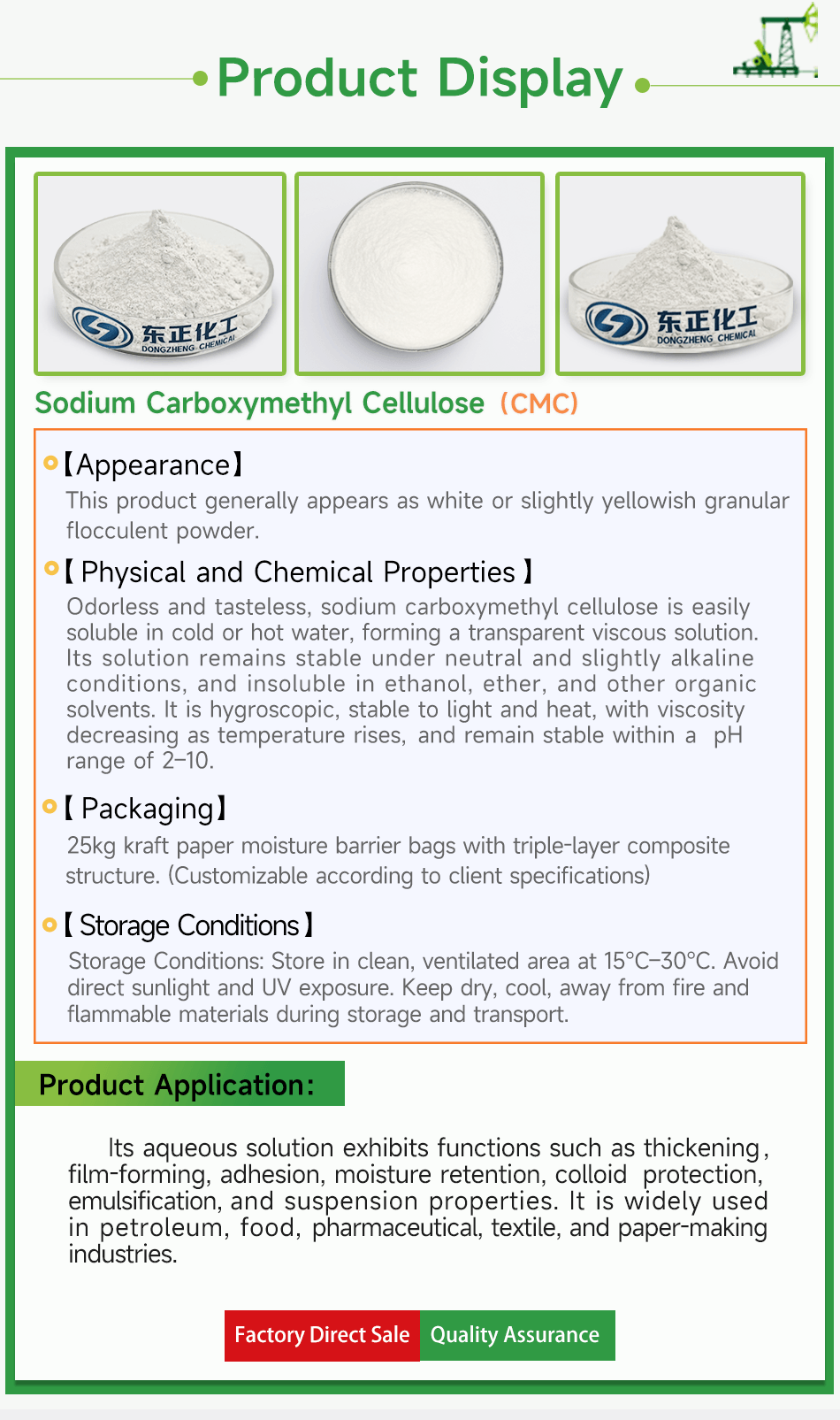

Appearance: This product generally appears as white or slightly yellowish granular flocculent powder.

Physical and Chemical Properties:

Odorless and tasteless, sodium carboxymethyl cellulose is easily soluble in cold or hot water, forming a transparent viscous solution. Its solution remains stable under neutral and slightly alkaline conditions, and insoluble in ethanol, ether, and other organic solvents. It is hygroscopic, stable to light and heat, with viscosity decreasing as temperature rises, and remain stable within a pH range of 2–10.

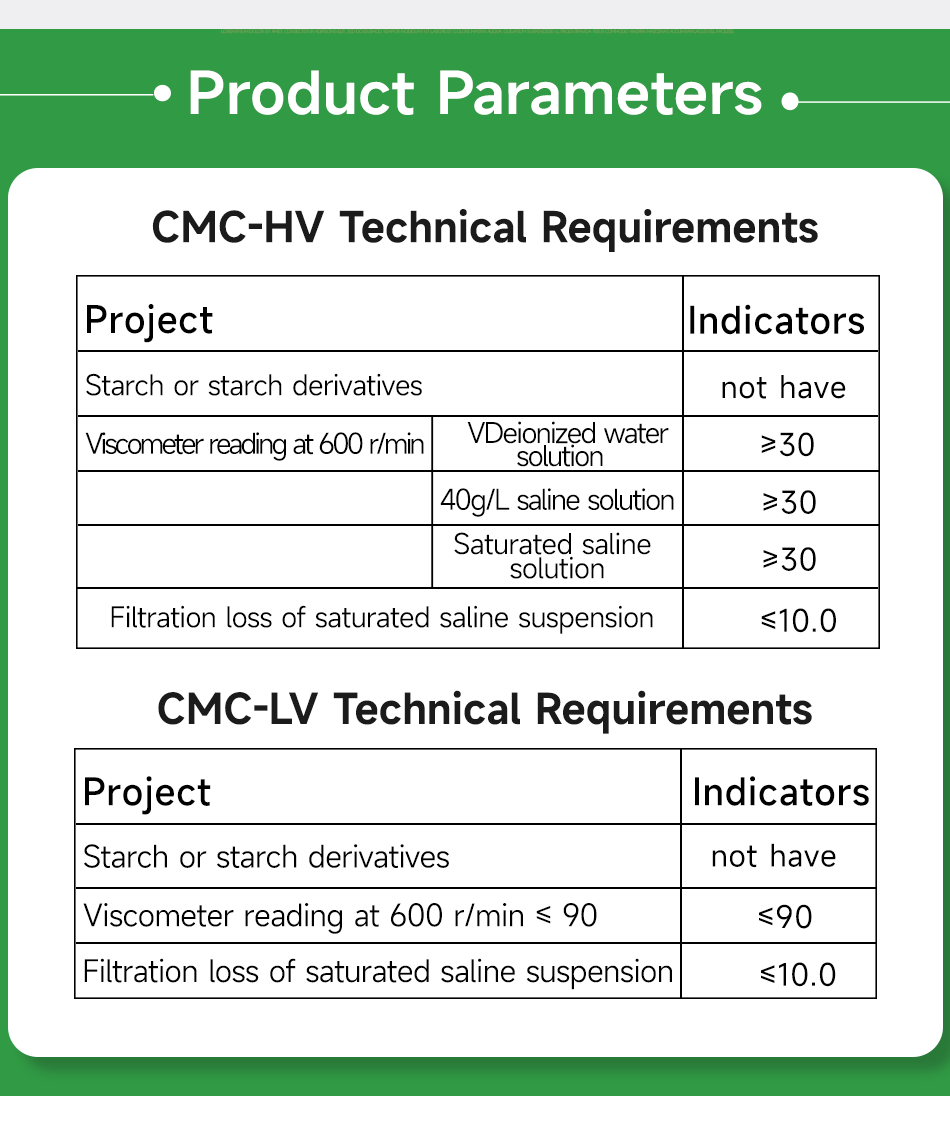

CMC-HV Technical Specifications

| Item | Specification | |

| Starch or starch derivatives | None | |

Viscometer 600 r/min sensitivity value | Deionized water solution | ≥30 |

| 40g/L brine solution | ≥30 | |

Saturated brine solution | ≥30 | |

| Fluid loss in saturated brine suspension | ≤10.0 | |

CMC-LV Technical Specifications

| Item | Specification |

| Starch or starch derivatives | None |

Viscometer 600 r/min sensitivity value | ≤90 |

| Fluid loss in saturated brine suspension | ≤10.0 |

Applications: Its aqueous solution exhibits functions such as thickening, film-forming, adhesion, moisture retention, colloid protection, emulsification, and suspension properties. It is widely used in petroleum, food, pharmaceutical, textile, and paper-making industries.

Specific Functions:

1. Suspension stabilizer for oil drilling muds

Sodium CMC-enhanced drilling fluids exhibit excellent stability, maintaining their ability to reduce fluid loss even at temperatures exceeding 150°C. They facilitate the formation of thin yet tough, low-permeability filter cakes on wellbore walls, thereby sustaining low fluid loss.

Sodium CMC-enhanced drilling fluids exhibit excellent rheological behavior and suspension stability, demonstrate strong resistance to contamination by various soluble salts, and are minimally affected by microbial degradation.

Sodium CMC-enhanced drilling fluids deliver superior viscosity build-up. Specifically, low-viscosity/high-DS grades optimize performance in weighted mud systems by providing exceptional fluid-loss control.

2. Oilfield fracturing chemicals

This product rapidly enhances fracturing fluid viscosity to efficiently transport proppants into well fractures. It establishes permeable channels, rapidly reduces fluid loss, and accelerates reservoir pressure buildup for effective pressure transmission. With zero residue and no formation damage, it serves as a high-performance alternative to guar gum and polyacrylamide.

Product Advantages:

1. Eco-friendly, non-toxic, harmless and odorless.

2. Excellent fluidity, salt resistance, antibacterial properties, easy to use.

3. Low dosage requirement, high yield efficiency, excellent viscosity-building and filtration-control performance.

Usage and Dosage: Add 0.2%–0.5%

Packaging:

25kg kraft paper moisture barrier bags with triple-layer composite structure. (Customizable according to client specifications)

Storage Conditions: Store in clean, ventilated area at 15°C–30°C. Avoid direct sunlight and UV exposure. Keep dry, cool, away from fire and flammable materials during storage and transport.