[Structural Formula] C57H104O9(CH2CH2O)n

[Molecular Weight] 2500

[Appearance] This product generally appears as light yellow, yellow, or milky white homogeneous free-flowing liquid.

[Physical and Chemical Properties]

Crude oil demulsifier is typically light yellow to brown liquid with a density of 0.9–1.1 g/ml and a kinematic viscosity below 100 mm²/s² at 20°C. It exhibits strong surface activity, primarily functioning to break crude oil-water emulsions, enabling efficient phase separation. Through rapid dispersion at the oil-water interface, it reduces interfacial tension, causing water droplets to break and coalesce, then settle to the tank bottom and separate from oil. This process enhances oil recovery and economic benefits.

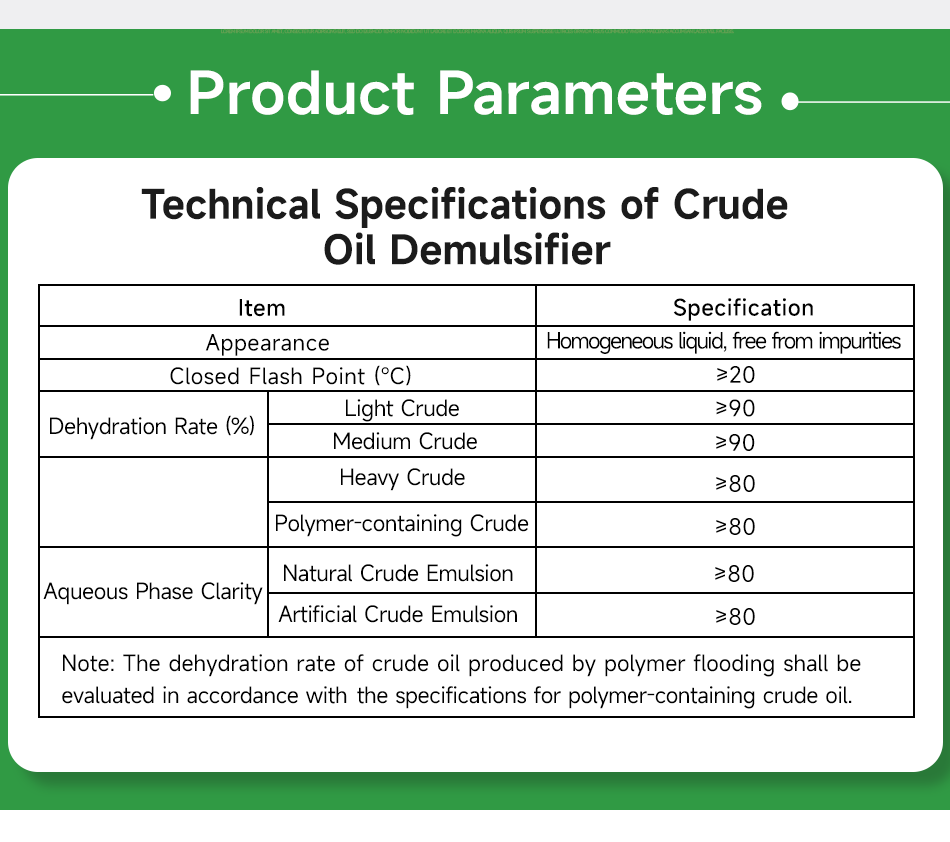

Technical Specifications of Crude Oil Demulsifier

| Item | Specification | |

| Appearance | Homogeneous liquid, free from impurities | |

| Closed Flash Point (℃) | ≥20 | |

| Dehydration Rate (%) | Light Crude | ≥90 |

| Medium Crude | ≥90 | |

Heavy Crude | ≥80 | |

| Polymer-containing Crude | ≥80 | |

| Aqueous Phase Clarity | Natural Crude Emulsion | Not lower than grade 1 |

Artificial Crude Emulsion | Not lower than grade 2 | |

| Note: The “dehydration rate” of produced crude oil from polymer flooding shall be evaluated in accordance with the specifications for polymer-containing crude oil. | ||

[Application]

Through chemical action, the product separates emulsified oil-water mixtures to dehydrate crude oil and reduce its water content for pipeline transport. It breaks down emulsions into water and oil phases by altering surface properties, eliminating emulsifiers, reducing interfacial tension, and changing rheological behavior—thus destabilizing emulsions and achieving separation.

[Product Advantages]

1. Effectively promote oil-water separation;

2. Improve crude oil flowability;

3. Reduce production costs;

4. Increase storage capacity;

5. Act quickly and steadily;

6. Highly adaptable and easy to use.

[Usage and Dosage]

The product can be dosed either as a diluted solution or through specialized injection equipment. Recommended dosage is from 50–100 ppm, with the optimal concentration determined by process system, crude oil type, and operational parameters.

[Packaging]

Packed in iron or plastic drums, available in 1000kg IBC tanks, 200kg and 25kg drums. Customized packaging available. Handle with care during transport; avoid impact and inversion.

[Storage Conditions]

Store in a dry, cool, and ventilated warehouse and keep away from fire and heat sources.