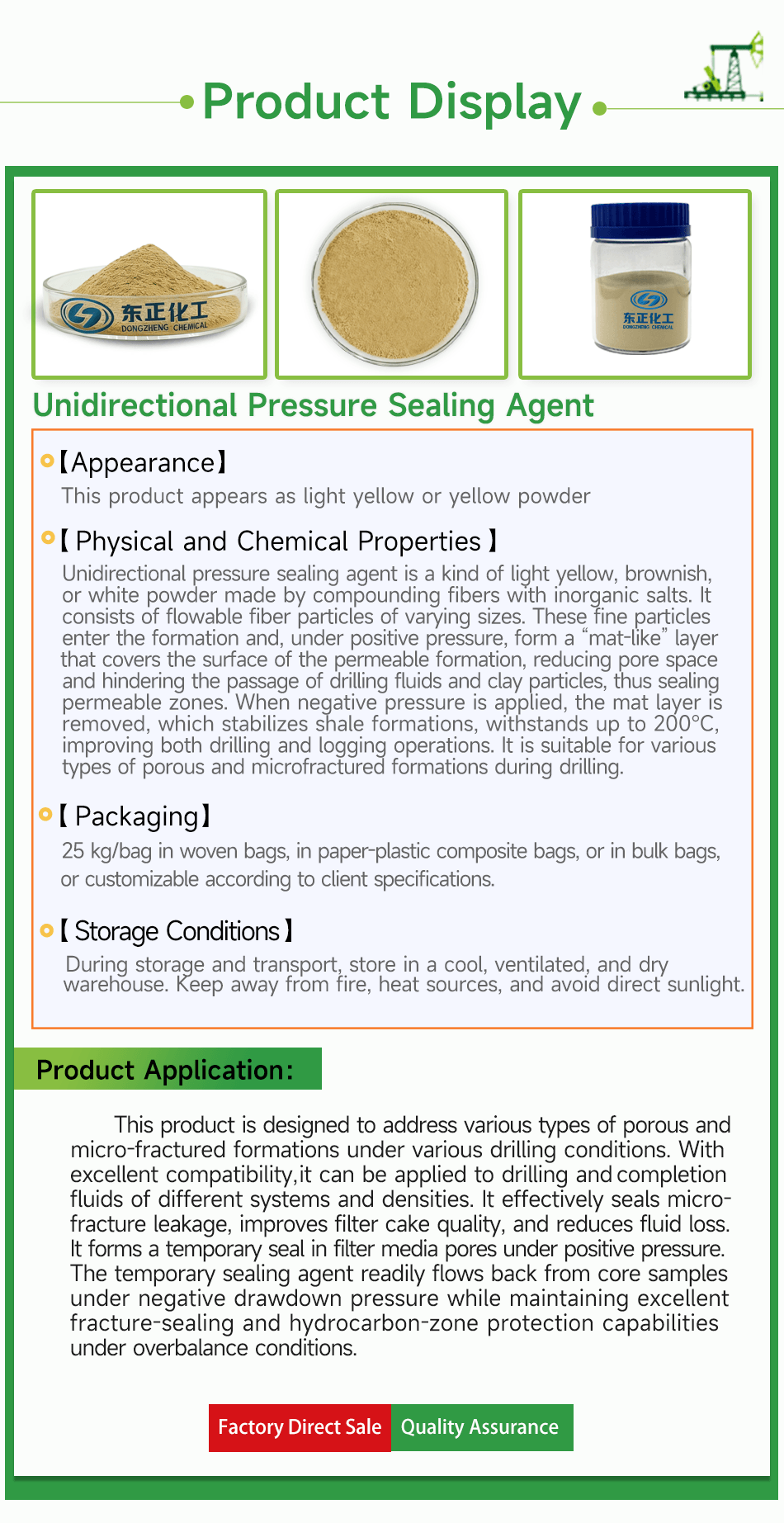

[Appearance] This product appears as light yellow or yellow powder.

[Physical and Chemical Properties]

Unidirectional pressure sealing agent is a kind of light yellow, brownish, or white powder made by compounding fibers with inorganic salts. It consists of flowable fiber particles of varying sizes. These fine particles enter the formation and, under positive pressure, form a “mat-like” layer that covers the surface of the permeable formation, reducing pore space and hindering the passage of drilling fluids and clay particles, thus sealing permeable zones. When negative pressure is applied, the mat layer is removed, which stabilizes shale formations, withstands up to 200°C, improving both drilling and logging operations. It is suitable for various types of porous and microfractured formations during drilling.

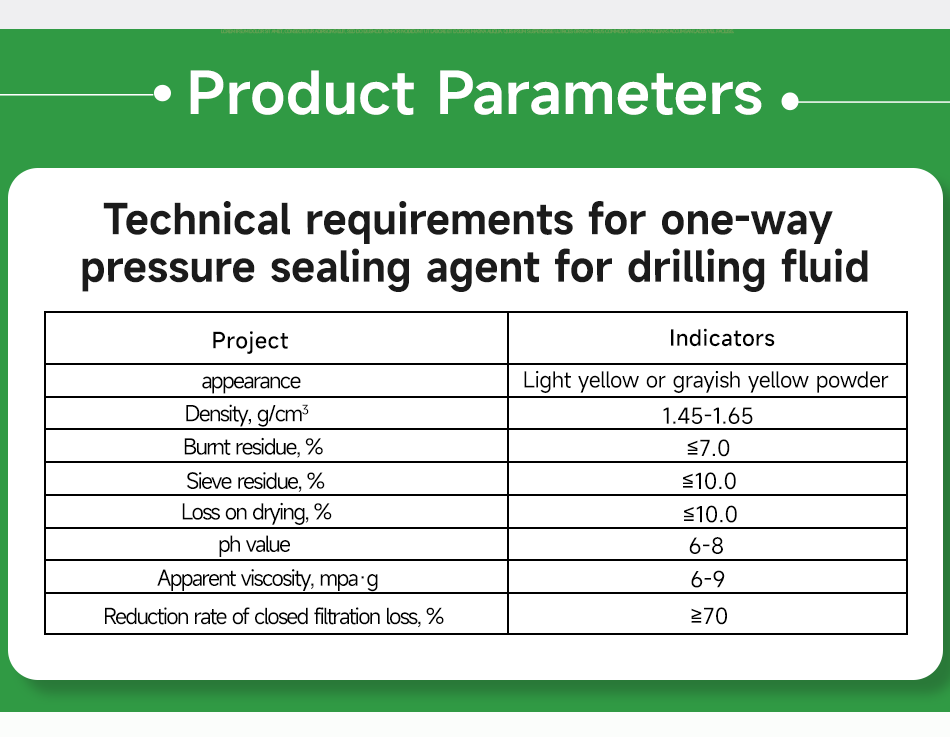

Technical Specifications of Unidirectional Pressure Sealing Agent

| Item | Specification |

| Appearance | Light yellow or grayish-yellow powder |

| Density, g/cm³ | 1.45-1.65 |

| Ash content, % ≤ | 7.0 |

Residue on sieve, % ≤ | 10.0 |

| Loss on drying, % ≤ | 10.0 |

| pH Value | 6-8 |

| Apparent viscosity, mPa·s | 6-9 |

| Filtration loss reduction rate, % ≥ | 70 |

[Applications]

This product is designed to address various types of porous and micro-fractured formations under various drilling conditions. With excellent compatibility, it can be applied to drilling and completion fluids of different systems and densities. It effectively seals micro-fracture leakage, improves filter cake quality, and reduces fluid loss. It forms a temporary seal in filter media pores under positive pressure. The temporary sealing agent readily flows back from core samples under negative drawdown pressure while maintaining excellent fracture-sealing and hydrocarbon-zone protection capabilities under overbalance conditions.

[Specific Functions]

1. Sealing Formation Seepage

After being added during drilling, it provides effective sealing under unidirectional pressure differentials. It is suitable for porous and micro-fractured formation losses under various conditions, effectively sealing microfractures and reducing mud filtration.

2. Improving Filter Cake Quality

This product improves filter cake quality and reduces fluid loss. Filter cake is a thin mud film formed during drilling, and this agent enhances its quality, thus reducing fluid loss and improving drilling efficiency.

3. Compatible with Various Systems

This agent has good compatibility and is suitable for various types and densities of drilling and completion fluids. This means it can be used under diverse drilling conditions without affecting mud performance.

4. Forming an Impermeable Barrier

It can quickly form a strong, impermeable sealing layer in formations, which blocks fluids and solids in the working fluid from invading the reservoir, protecting the reservoir from damage. This barrier can be removed through perforation and backflow, without affecting subsequent production.

5. No adverse effect on mud rheology

This product reduces fluid loss without altering mud rheology, ensuring smooth drilling operations.

6. Excellent Thermal Resistance

This agent tolerates high-temperature environments, typically up to 200°C, making it highly effective in deep and high-temperature wells.

[Product Advantages]

1. Significant rapid plugging effect;

2. Excellent compatibility and broad applicability;

3. Non-disruptive to mud rheology;

4. Eco-safe raw materials.

[Usage and Dosage]

1. For leakage prevention: 1%–2%.

2. For sealing sand layer pores and microfractures, and reservoir protection: 2%–4%.

3. For severe loss zones: 4%–6%.

[Packaging] 25 kg/bag in woven bags, in paper-plastic composite bags, or in bulk bags, or customizable according to client specifications.

[Storage Conditions] During storage and transport, store in a cool, ventilated, and dry warehouse. Keep away from fire, heat sources, and avoid direct sunlight.