[Molecular Weight] 1701.20

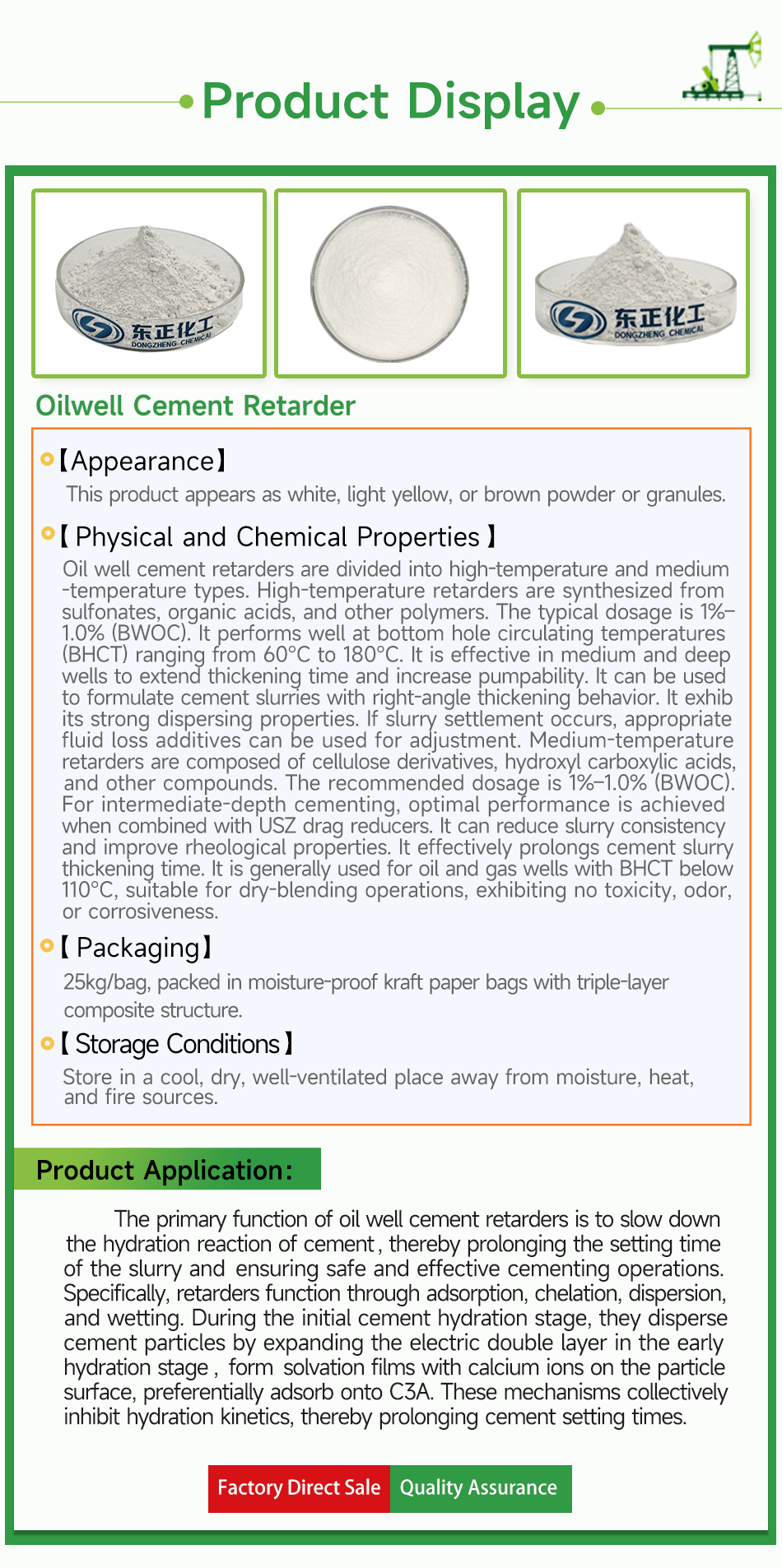

[Appearance] This product appears as white, light yellow, or brown powder or granules.

[Physical and Chemical Properties] Oil well cement retarders are divided into high-temperature and medium-temperature types. High-temperature retarders are synthesized from sulfonates, organic acids, and other polymers. The typical dosage is 1%–1.0% (BWOC). It performs well at bottom hole circulating temperatures (BHCT) ranging from 60℃ to 180℃. It is effective in medium and deep wells to extend thickening time and increase pumpability. It can be used to formulate cement slurries with right-angle thickening behavior. It exhibits strong dispersing properties. If slurry settlement occurs, appropriate fluid loss additives can be used for adjustment. Medium-temperature retarders are composed of cellulose derivatives, hydroxyl carboxylic acids, and other compounds. The recommended dosage is 1%–1.0% (BWOC). For intermediate-depth cementing, optimal performance is achieved when combined with USZ drag reducers. It can reduce slurry consistency and improve rheological properties. It effectively prolongs cement slurry thickening time. It is generally used for oil and gas wells with BHCT below 110℃, suitable for dry-blending operations, exhibiting no toxicity, odor, or corrosiveness.

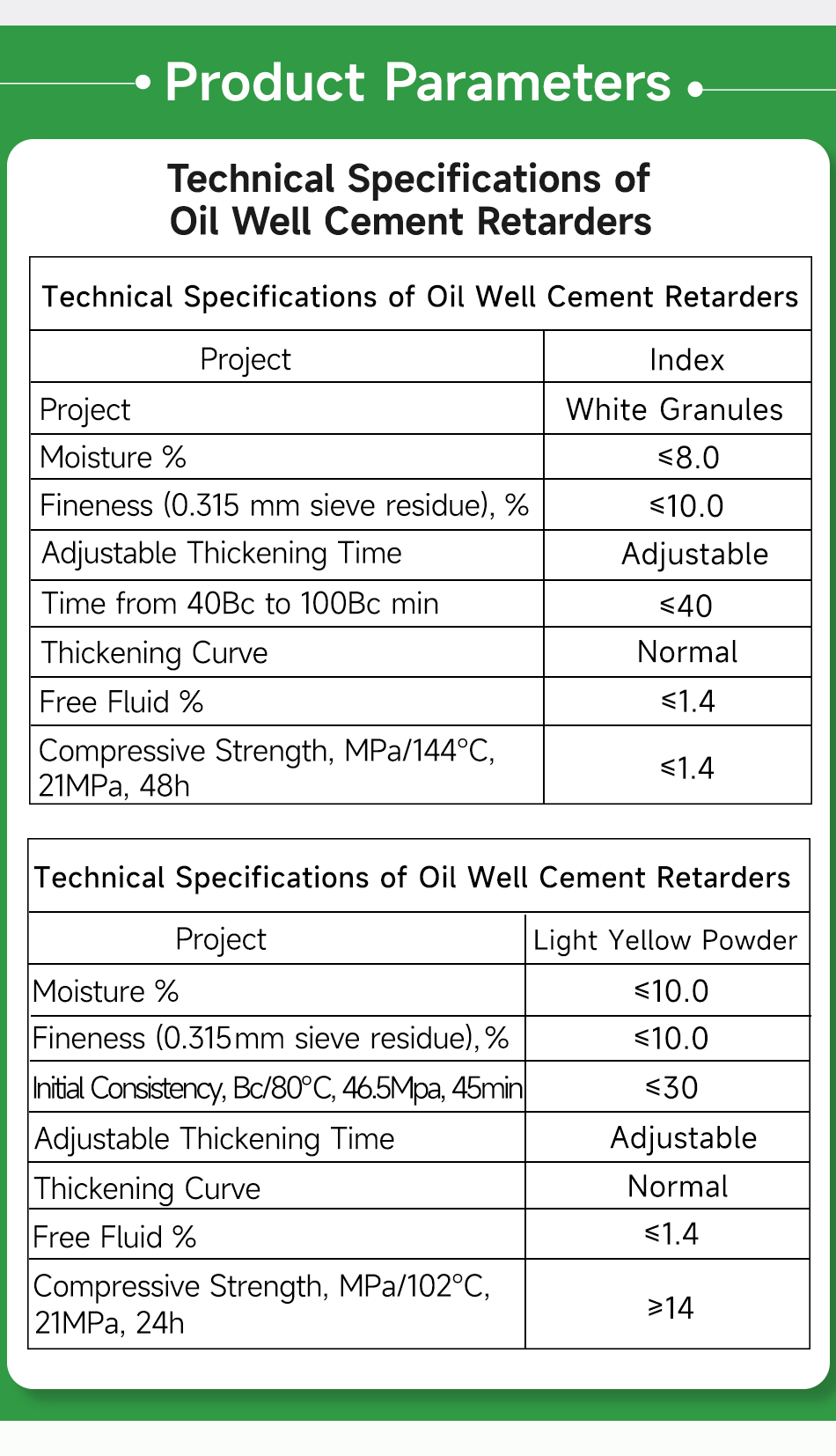

Technical Specifications of Oil Well Cement Retarders

| Technical Requirements for High-Temperature Cementing Retarder | |

| Item | Specification |

| Appearance | White Granules |

| Moisture, % | ≤8.0 |

| Fineness (0.315 mm sieve residue), % | ≤10.0 |

| Adjustable Thickening Time | Adjustable |

| Time from 40Bc to 100Bc, min | ≤40 |

| Thickening Curve | Normal |

| Free Fluid, % | ≤1.4 |

| Compressive Strength, MPa/144℃, 21MPa, 48h | ≥14 |

| Technical Requirements for Medium-Temperature Cementing Retarder (Oilwell Cement) | |

| Appearance | Light yellow powder |

| Moisture, % | ≤10.0 |

| Fineness (0.315 mm sieve residue), % | ≤10.0 |

| Initial Consistency, Bc/80℃, 46.5Mpa, 45min | ≤30 |

| Adjustable Thickening Time | Adjustable |

| Thickening Curve | Normal |

| Free Fluid, % | ≤1.4 |

| Compressive Strength, MPa/102℃, 21MPa, 24h | ≥14 |

[Application] The primary function of oil well cement retarders is to slow down the hydration reaction of cement, thereby prolonging the setting time of the slurry and ensuring safe and effective cementing operations. Specifically, retarders function through adsorption, chelation, dispersion, and wetting. During the initial cement hydration stage, they disperse cement particles by expanding the electric double layer in the early hydration stage, form solvation films with calcium ions on the particle surface, preferentially adsorb onto C3A. These mechanisms collectively inhibit hydration kinetics, thereby prolonging cement setting times.

[Functional Effects]

1. Adjusting Set Time. Retarders significantly extend cement slurry setting time, providing greater operational flexibility and ensuring precision in every construction phase.

2. Enhancing Cementing Quality. They promote uniform cement particle distribution, reduce cracks and voids, enhance overall integrity, and prevent formation fluid intrusion.

3. Adapting to Complex Geology: They are effective in high-temperature, high-pressure, or corrosive environments to ensure reliable cementing.

[Product Advantages]

Prolongs slurry setting time;

Improves cementing quality;

Suitable for complex formations;

Available in various types and functionalities;

No negative impact on cement strength.

[Usage and Dosage] Typical dosage: 0.3%–1.5% (BWOC)

[Packaging] 25kg/bag, packed in moisture-proof kraft paper bags with triple-layer composite structure.

[Storage Conditions] Store in a cool, dry, well-ventilated place away from moisture, heat, and fire sources.