[Appearance]

This product typically appears as transparent, pale yellow, yellow to reddish-brown, free-flowing uniform liquid.

[Product Characteristics]

The biocide used for hydraulic fracturing features low toxicity and easy degradability. It possesses dual-action antimicrobial performance, effectively tackling the drug resistance of sulfate-reducing bacteria (SRB), and provides significant inhibition of bacterial growth in oilfield water injection and production systems. It is especially suitable for polymer-containing oilfield wastewater treatment and reinjection systems.

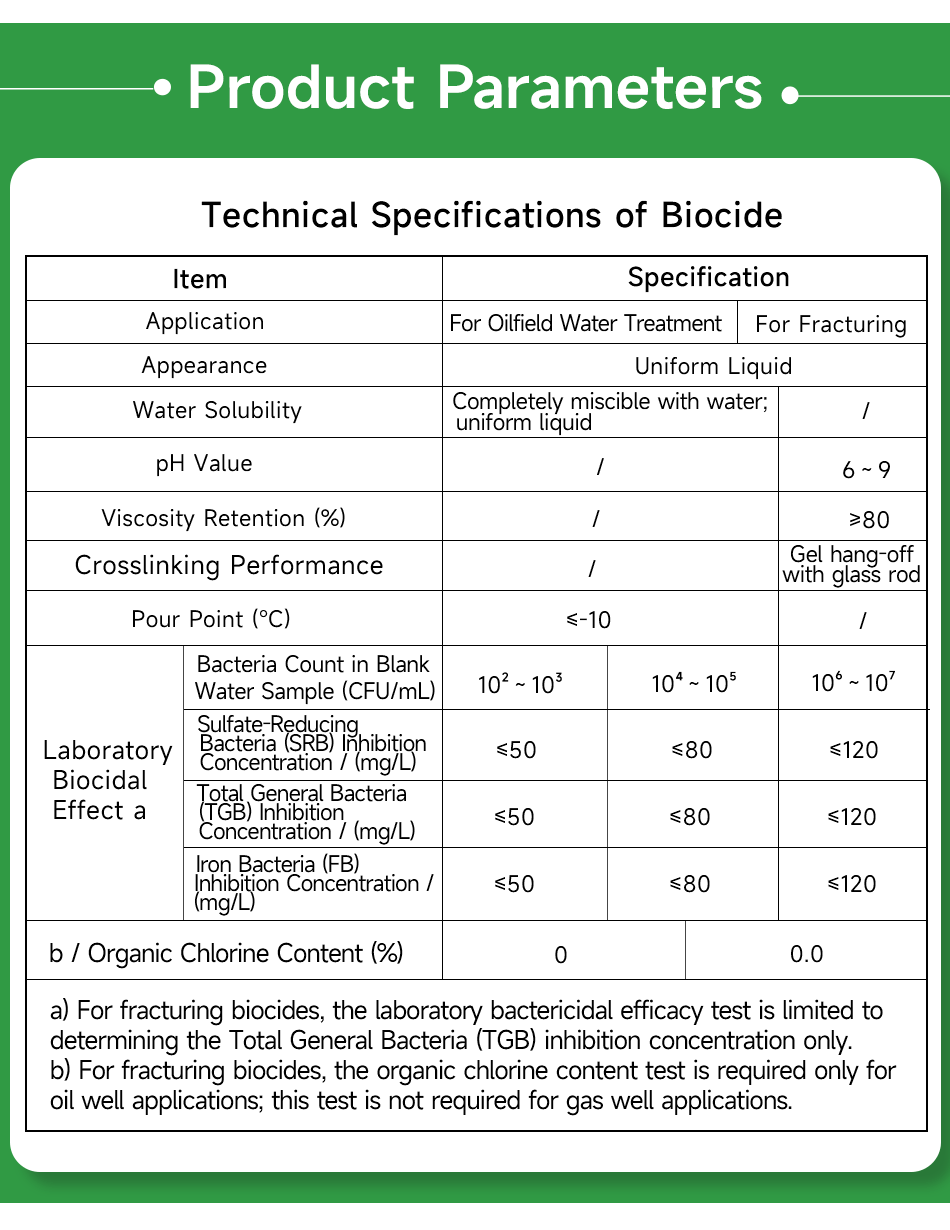

Technical Specifications of Biocide

Item | Specification | |||

| For Oilfield Water Treatment | For Fracturing | |||

| Appearance | Uniform Liquid | |||

| Water Solubility | Completely miscible with water; uniform liquid | / | ||

| Corrosiveness | Non-corrosive | / | ||

| pH Value | / | 6-9 | ||

| Viscosity Retention (%) | / | ≥80 | ||

| Crosslinking Performance | / | Gel hang-off with glass rod | ||

| Pour Point (℃) | ≤-10 | / | ||

| Laboratory Biocidal Effect a | Bacteria Count in Blank Water Sample (CFU/mL) | 10²-10³ | 10⁴-10⁵ | 10⁶-10⁷ |

| Inhibitory Concentration for Sulfate-Reducing Bacteria (mg/L) | ≤50 | ≤80 | ≤120 | |

Inhibitory Concentration for Saprophytic Bacteria (mg/L) | ≤50 | ≤80 | ≤120 | |

| Inhibitory Concentration for Iron Bacteria (mg/L) | ≤50 | ≤80 | ≤120 | |

| Organic Chlorine Content (b /%) | 0 | 0.0 | ||

| a. For fracturing biocides, the indoor bactericidal effectiveness test is limited to determining the inhibitory concentration against heterotrophic bacteria (TGB). | ||||

| b. For fracturing biocides, the organic chlorine content test is required only for oil well applications and is not applicable for gas well applications. | ||||

[Application]

Fracturing biocides are mainly used to control microbial growth, prevent metal corrosion, reduce pipeline blockages, inhibit sludge formation, and enhance oilfield production output and quality. By inhibiting or killing SRB, FB, and TGB, biocides reduce equipment corrosion, sludge formation, and clogging, thereby protecting oilfield equipment and improving oil recovery efficiency.

[Product Advantages]

1. Sterilize and disinfects to improve water quality;

2. Effectively reduce polymer viscosity, enhancing oil recovery;

3. Prevent pipeline corrosion;

4. Water-soluble, colorless, odorless, non-toxic, and environmentally friendly.

[Usage and Dosage]

Recommended concentration: 50–100 ppm. At a dosage of 20 ppm, it can still maintain a certain sterilization rate after one month.

[Packaging]

This product is available in 1000 kg IBC totes, 200 kg and 25 kg drums. Customized packaging is available upon request.

[Storage Conditions]

Store in a cool, dry, clean, and shaded place. Keep containers tightly closed at room temperature. Shelf life: 2 years.