[Molecular Formula] (C₈H₁₆ClN)ₙ

[Molecular Weight] 491.065

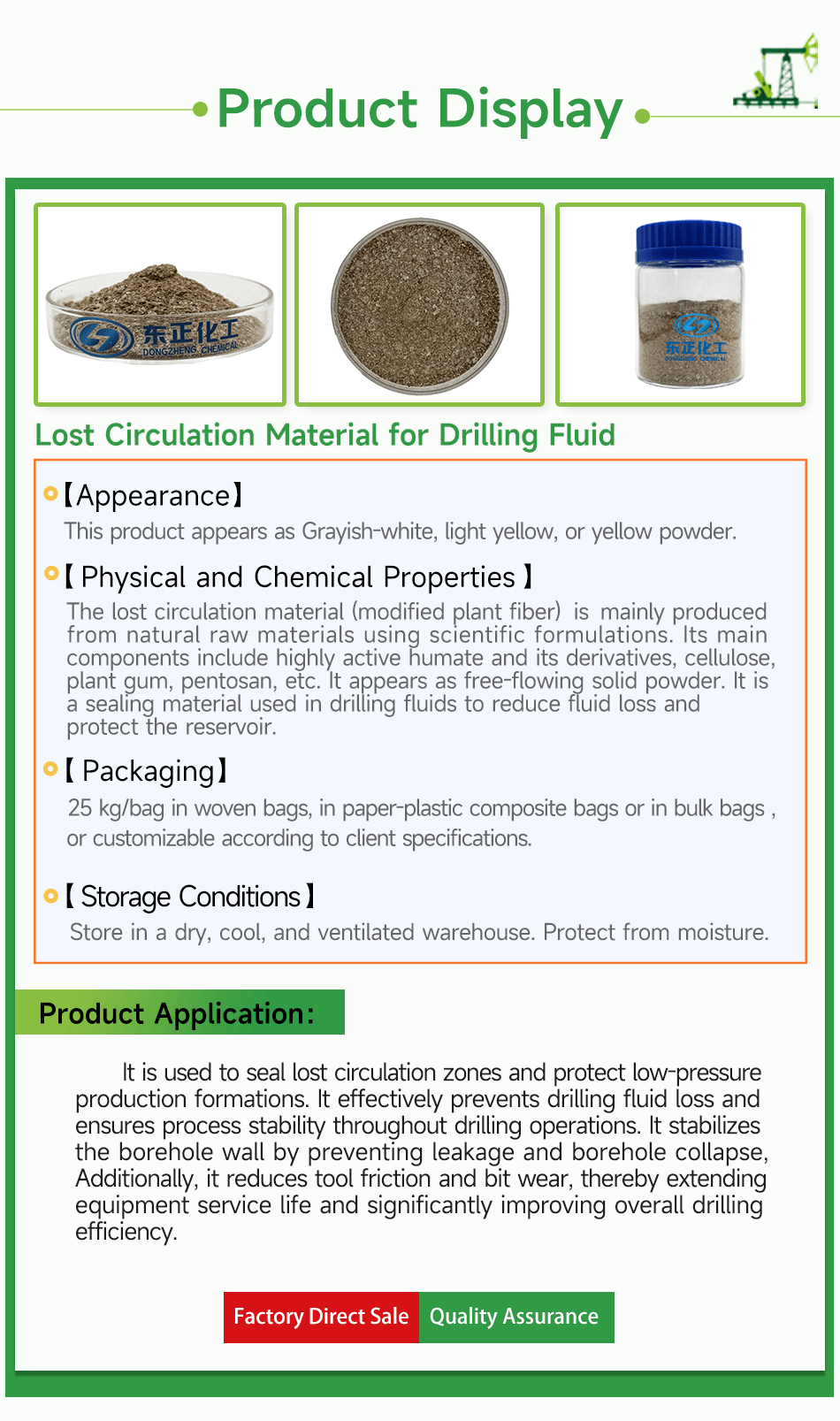

[Appearance] This product appears as Grayish-white, light yellow, or yellow powder.

[Physical and Chemical Properties]

The lost circulation material (modified plant fiber) is mainly produced from natural raw materials using scientific formulations. Its main components include highly active humate and its derivatives, cellulose, plant gum, pentosan, etc. It appears as free-flowing solid powder. It is a sealing material used in drilling fluids to reduce fluid loss and protect the reservoir.

Technical Specifications of Lost Circulation Material for Drilling Fluid

| Physicochemical Indexes | |

| Item | Specification |

| Appearance | Light yellow or grayish-yellow powder |

| Residue on 0.28 mm sieve, % ≤ | ≦10.0 |

pH Value | 6.0-8.0 |

| Moisture, % ≤ | ≦8.0 |

| Ash Content, % ≤ | ≦7.0 |

| Performance Indicators | |

Apparent Viscosity Increase Rate, % ≤ | ≦20 |

| Density, g/cm³ ≥ | ≧1.00 |

| Sealing Fluid Loss (30 min), mL ≤ | ≦30 |

[Applications]

It is used to seal lost circulation zones and protect low-pressure production formations. It effectively prevents drilling fluid loss and ensures process stability throughout drilling operations. It stabilizes the borehole wall by preventing leakage and borehole collapse, Additionally, it reduces tool friction and bit wear, thereby extending equipment service life and significantly improving overall drilling efficiency.

[Specific Functions]

1. Sealing Formation Fractures and Pores

This material is mainly used to seal fractures and pores in formations to prevent fluid loss during drilling. It reacts quickly to form a tough sealing layer, ensuring the smooth progress of drilling operations.

2. Improving Drilling Efficiency:

The application of lost circulation materials (LCM) while drilling can significantly enhance drilling efficiency. Under complex formation conditions, fractures and pores can cause severe fluid loss, substantially impacting drilling progress. By using LCMs, fluid loss is effectively reduced, ensuring proper circulation and cooling functions of the fluid, hereby improving overall drilling speed.3. Enhancing Drilling Safety:

Fractures and pores can cause fluid loss, and may trigger wellbore collapse and other safety issues. The lost circulation material reinforces the borehole wall effectively to prevent collapse accidents, thus ensuring safe drilling operations.

[Product Advantages]

1. It is made from environmentally safe raw materials with excellent biodegradability, and non-toxic to humans and harmless to the environment.

2. It can quickly plug pores and micro-fractures for immediate lost circulation control.

3. It can significantly reduce fluid loss without affecting rheological properties of the mud, with excellent temperature resistance;

4. It can quickly form a strong, impermeable barrier to prevent invasion of both liquid and solid components into the formation, easily removed through perforation backflow without reservoir damage.

[Usage and Dosage]

1. For leakage prevention: 1%–2%.

2. For sealing sand layer pores and micro-fractures, and for reservoir protection: 2%–4%.

3. For severe loss zones: 4%–6%.

[Packaging] 25 kg/bag in woven bags, in paper-plastic composite bags or in bulk bags , or customizable according to client specifications.

[Storage] Store in a dry, cool, and ventilated warehouse. Protect from moisture.