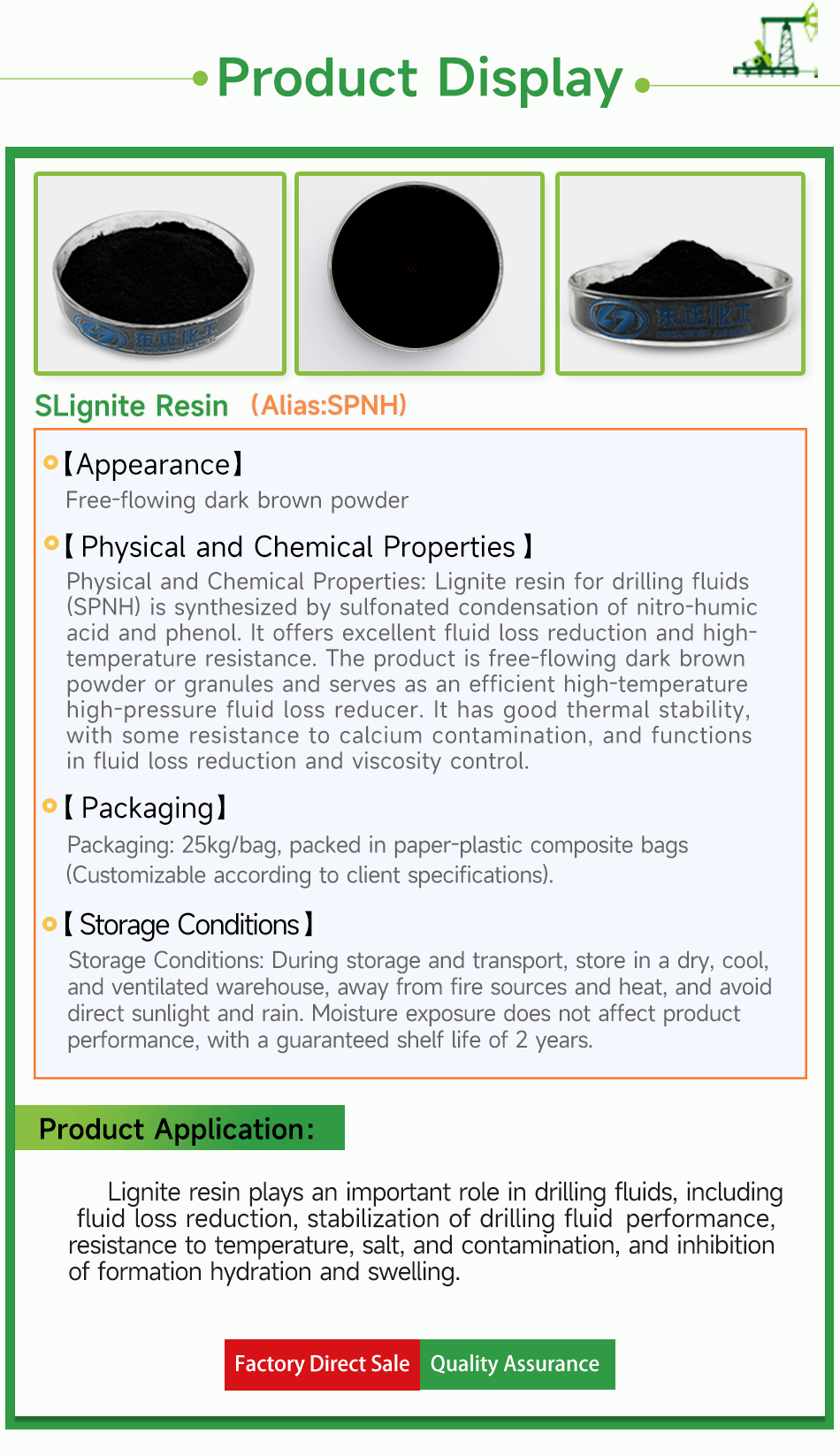

Appearance: Free-flowing dark brown powder.

Physical and Chemical Properties:

Lignite resin for drilling fluids (SPNH) is synthesized by sulfonated condensation of nitro-humic acid and phenol. It offers excellent fluid loss reduction and high-temperature resistance. The product is free-flowing dark brown powder or granules and serves as an efficient high-temperature high-pressure fluid loss reducer. It has good thermal stability, with some resistance to calcium contamination, and functions in fluid loss reduction and viscosity control.

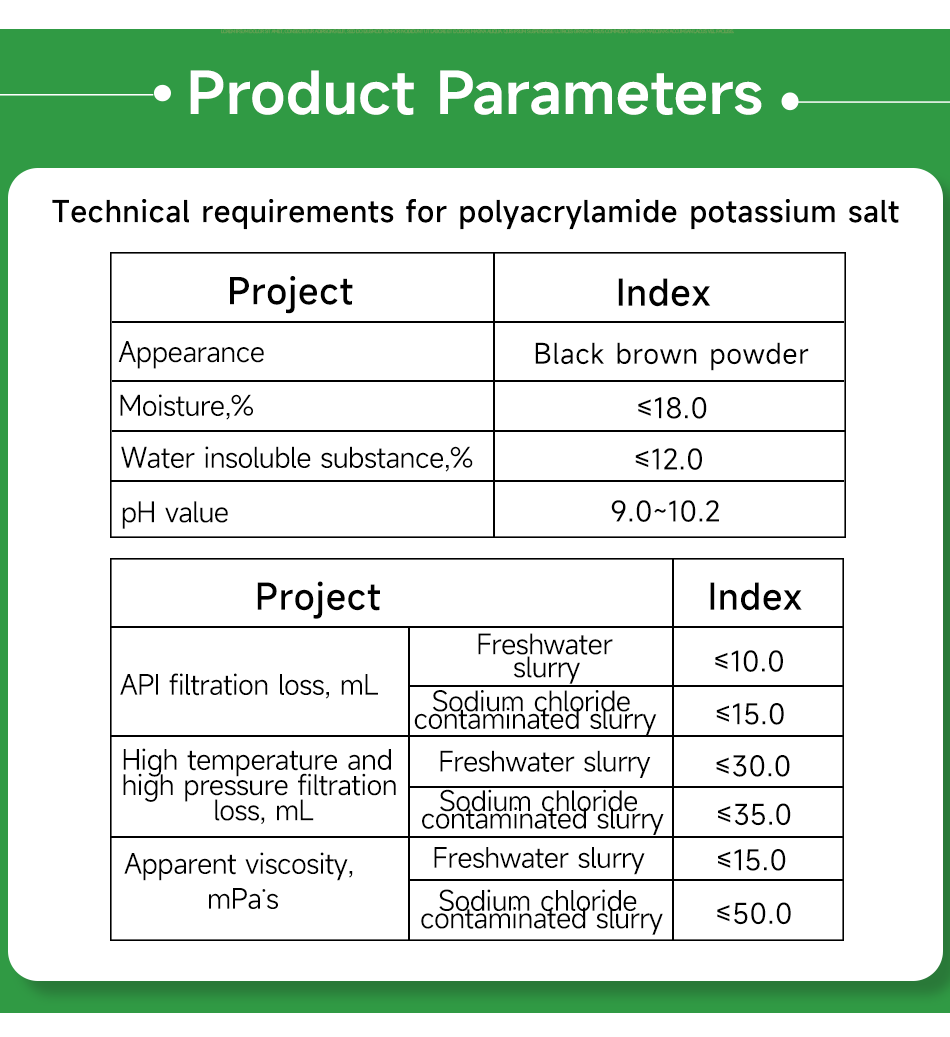

Technical Specifications of Lignite Resin

| Item | Specification | |

| Appearance | Dark brown powder | |

| Moisture, % | ≤18.0 | |

| Water Insolubles, % | ≤12.0 | |

| pH Value | 9.0-10.2 | |

API Fluid Loss, mL | In Freshwater Slurry | ≤10.0 |

In NaCl Contaminated Slurry | ≤15.0 | |

| High Temp High Pressure Fluid Loss, mL | In Freshwater Slurry | ≤30.0 |

| In NaCl Contaminated Slurry | ≤35.0 | |

| Apparent Viscosity, mPa·s | In Freshwater Slurry | ≤15.0 |

| In NaCl Contaminated Slurry | ≤50.0 | |

Applications: Lignite resin plays an important role in drilling fluids, including fluid loss reduction, stabilization of drilling fluid performance, resistance to temperature, salt, and contamination, and inhibition of formation hydration and swelling.

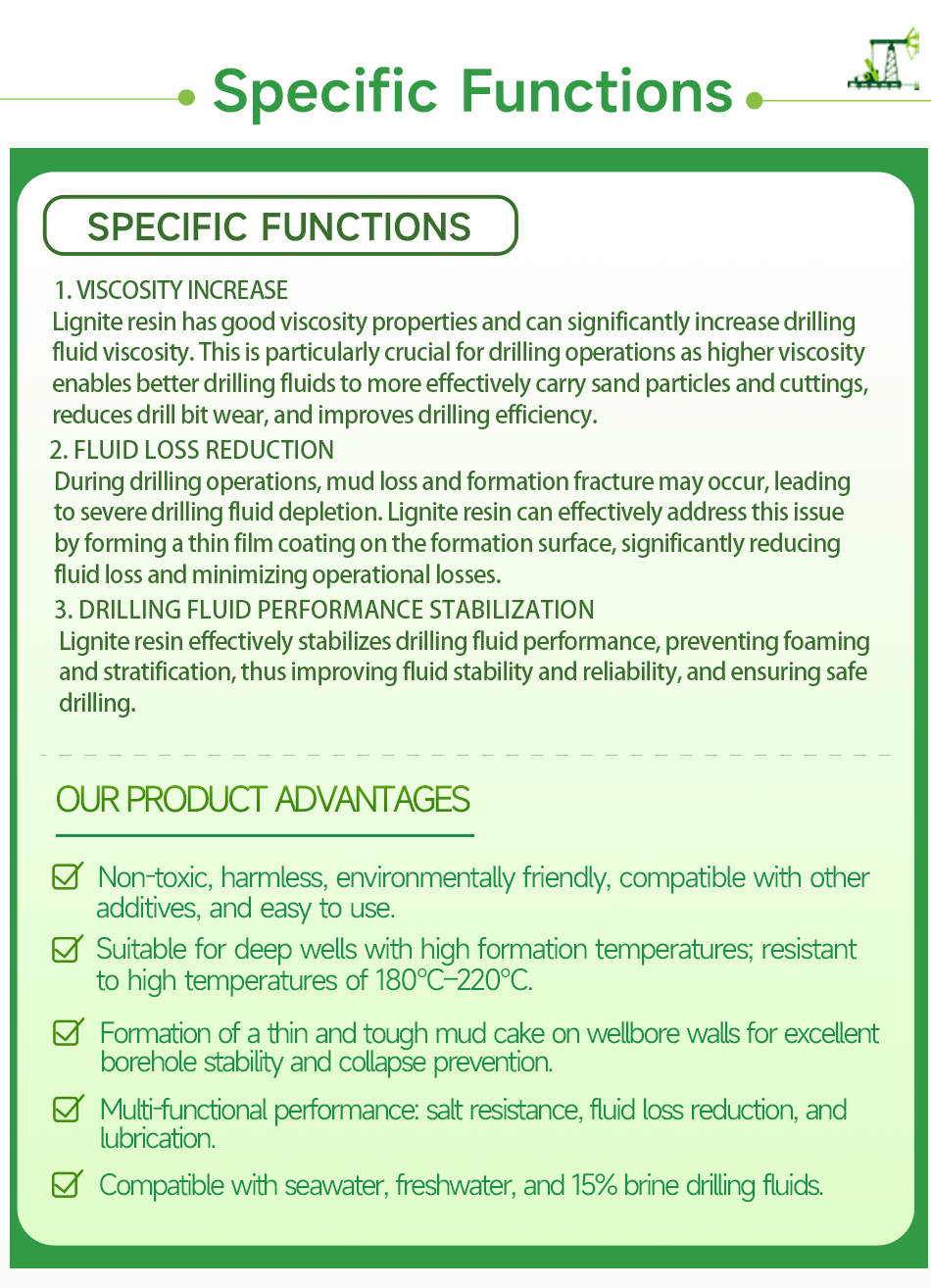

Specific Functions:

1. Viscosity Increase

Lignite resin has good viscosity properties and can significantly increase drilling fluid viscosity. This is particularly crucial for drilling operations as higher viscosity enables better drilling fluids to more effectively carry sand particles and cuttings, reduces drill bit wear, and improves drilling efficiency.

2. Fluid Loss Reduction

During drilling operations, mud loss and formation fracture may occur, leading to severe drilling fluid depletion. Lignite resin can effectively address this issue by forming a thin film coating on the formation surface, significantly reducing fluid loss and minimizing operational losses.

3. Drilling Fluid Performance Stabilization

Lignite resin effectively stabilizes drilling fluid performance, preventing foaming and stratification, thus improving fluid stability and reliability, and ensuring safe drilling.

Product Advantages:

1. Non-toxic, harmless, environmentally friendly, compatible with other additives, and easy to use.

2. Suitable for deep wells with high formation temperatures; resistant to high temperatures of 180°C–220°C.

3. Formation of a thin and tough mud cake on wellbore walls for excellent borehole stability and collapse prevention.

4. Multi-functional performance: salt resistance, fluid loss reduction, and lubrication.

5. Compatible with seawater, freshwater, and 15% brine drilling fluids.

Usage and Dosage: Recommended dosage is 2%–4%; higher dosage may be used in brine-based mud systems.

Packaging: 25kg/bag, packed in paper-plastic composite bags (Customizable according to client specifications).

Storage Conditions: During storage and transport, store in a dry, cool, and ventilated warehouse, away from fire sources and heat, and avoid direct sunlight and rain. Moisture exposure does not affect product performance, with a guaranteed shelf life of 2 years.